-

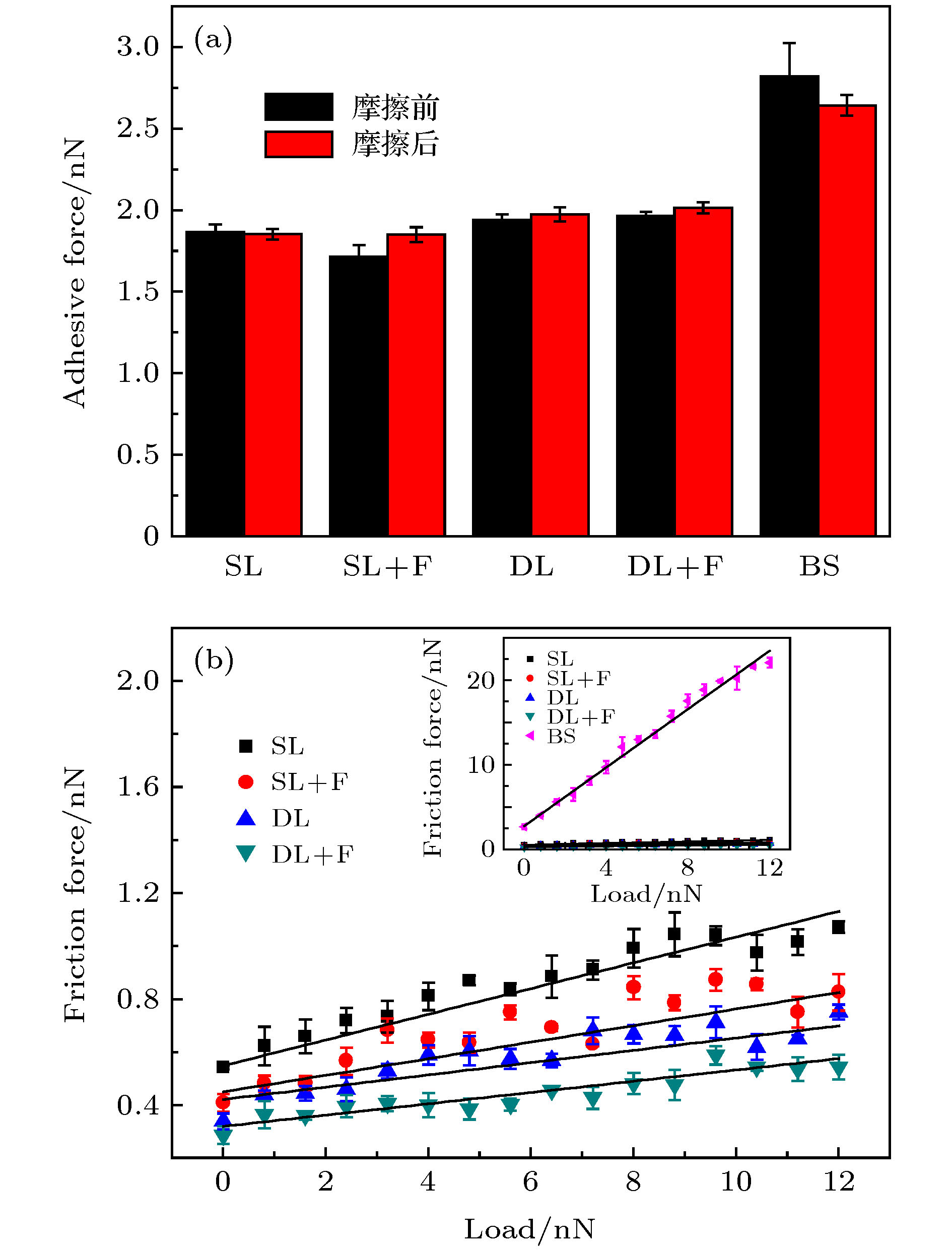

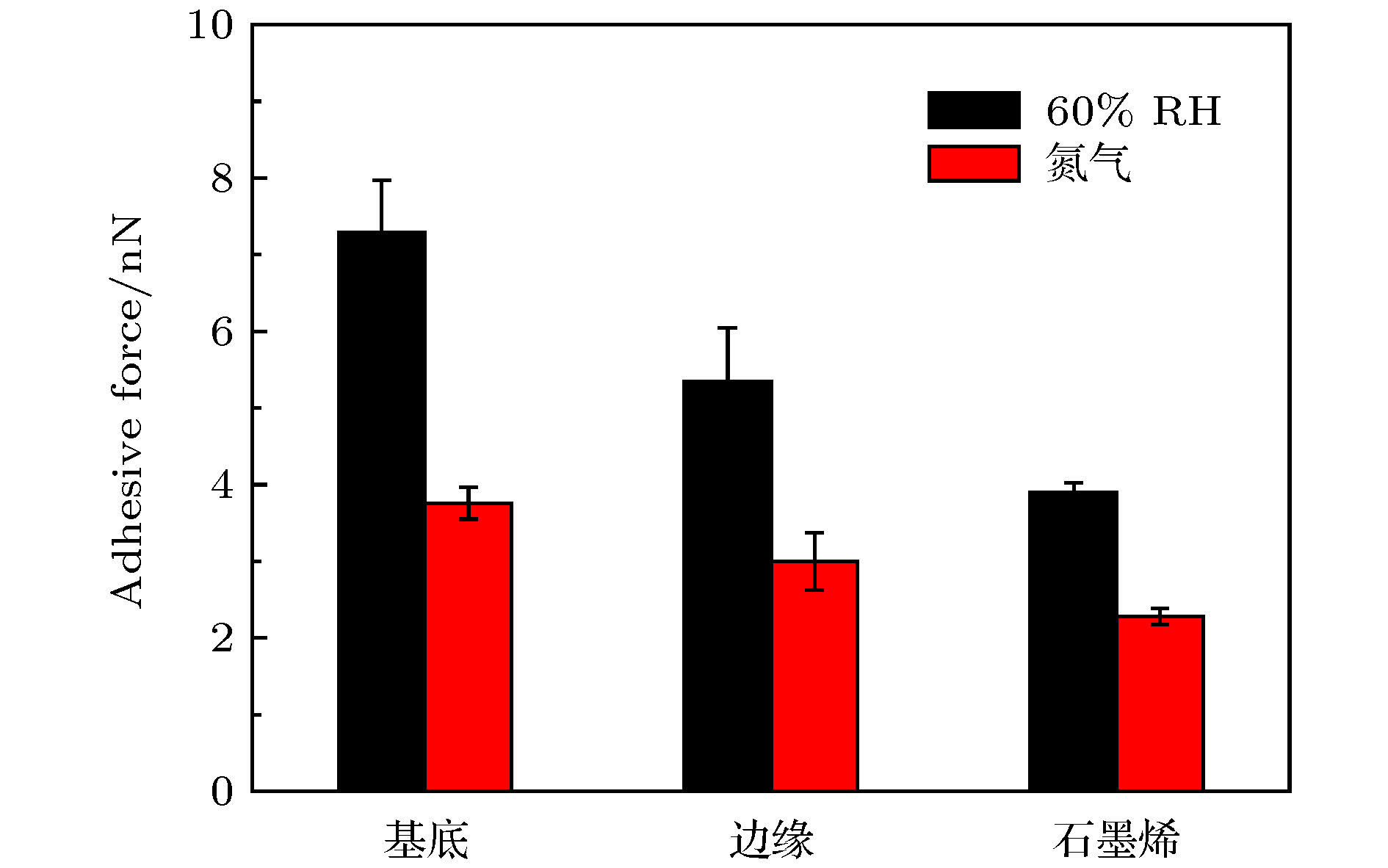

本文用原子力显微镜研究了空气和氮气两种不同气氛环境下的机械剥离石墨烯粘附力, 发现氮气环境下的粘附力更小, 且石墨烯边缘的粘附力比内部区域大. 在氮气环境下探究了折叠石墨烯粘附力与层数的关系及其摩擦性能, 结果表明粘附力与折叠石墨烯层数无明显关系, 折叠石墨烯各区域的摩擦性能都远超二氧化硅基底, 且单层、单层上折叠、双层以及双层上折叠区域的摩擦系数依次降低, 分别为0.049, 0.031, 0.023和0.021, 摩擦力也依次降低, 折叠处由于层与层之间的结合力弱于相同层数的石墨烯, 摩擦性能有所降低, 但未发现粘附力与摩擦力之间的明显关系. 在采用尖针和球针测量粘附力时, 测量历史不会对后续粘附力产生明显影响. 对空气环境下出现的新鲜折叠石墨烯的研究表明新鲜折叠石墨烯的折叠区域摩擦力较未折叠区域显著增大.Atomic force microscope was used to study the adhesion of mechanical exfoliated graphene under two different atmosphere conditions, air and nitrogen. It was found that the adhesion under nitrogen was smaller. The adhesion of graphene edge was larger than that of the inner region. The relationship between the adhesion of folded graphene and the number of layers along with its frictional properties were investigated under nitrogen atmosphere. The results showed that the adhesion was independent of the number of folded graphene layers. The frictional properties of each area of the folded graphene were far beyond the SiO2 substrate. The friction coefficients of the single layer, the fold on single layer, the double layers and the fold on double layers regions were successively decreased, which were 0.049, 0.031, 0.023 and 0.021 respectively. The friction forces were successively decreased as well. The frictional property of the folded graphene was weaker than the unfolded graphene of same number of layers due to the weaker bonding force between the layers. When measuring the adhesion with a sharp tip or a ball tip, the measurement history of adhesion had little influence on subsequent adhesion. Studies on freshly folded graphene in the air showed that the friction force of the folded region was significantly higher than that of the unfolded region.

-

Keywords:

- atomic force microscope /

- folded graphene /

- adhesion /

- nanotribology

[1] Novoselov K S, Geim A K, Morozov S V, Jiang D, Zhang Y, Dubonos S V, Grigorieva I V, Firsov A A 2004 Science 306 666

Google Scholar

Google Scholar

[2] Zang X, Zhou Q, Chang J, Liu Y, Lin L 2015 Microelectron. Eng. 132 192

Google Scholar

Google Scholar

[3] Banhart F, Kotakoski J, Krasheninnikov A V 2011 ACS Nano 5 26

Google Scholar

Google Scholar

[4] Deng S K, Berry V 2016 Mater. Today 19 197

Google Scholar

Google Scholar

[5] Vasic B, Zurutuza A, Gajic R 2016 Carbon 102 304

Google Scholar

Google Scholar

[6] 覃业宏, 唐超, 张春小, 孟利军, 钟建新 2015 64 016804

Google Scholar

Google Scholar

Qin Y H, Tang C, Zhang C X, Meng L J, Zhong J X 2015 Acta Phys. Sin. 64 016804

Google Scholar

Google Scholar

[7] Yi H, Zhang X, Zhao Y, Liu Y, Song S 2017 J. Colloid Interface. Sci. 499 62

Google Scholar

Google Scholar

[8] Gajurel P, Kim M, Wang Q, Dai W T, Liu H T, Cen C 2017 Adv. Funct. Mater. 27 8

[9] Zheng F, Duan F L 2019 Tribol. Int. 134 87

Google Scholar

Google Scholar

[10] Kavalur A, Kim W K 2017 Comput. Mater. Sci. 137 346

Google Scholar

Google Scholar

[11] Tripathi M, Awaja F, Bizao R A, Signetti S, Iacob E, Paolicelli G, Valeri S, Dalton A, Pugno N M 2018 ACS Appl. Mater. Interfaces 10 44614

Google Scholar

Google Scholar

[12] Long F, Yasaei P, Yao W T, Salehi-Khojin A, Shahbazian-Yassar R 2017 ACS Appl. Mater. Interfaces 9 20922

Google Scholar

Google Scholar

[13] Hutter J L, Bechhoefer J 1993 Rev. Sci. Instrum. 64 1868

Google Scholar

Google Scholar

[14] Varenberg M, Etsion I, Halperin G 2003 Rev. Sci. Instrum. 74 3362

Google Scholar

Google Scholar

[15] Butt H J, Cappella B, Kappl M 2005 Surf. Sci. Rep. 59 1

Google Scholar

Google Scholar

[16] Farshchi-Tabrizi M, Kappl M, Cheng Y, Gutmann J, Butt H J 2006 Langmuir 22 2171

Google Scholar

Google Scholar

[17] Munz M, Giusca C E, Myers-Ward R L, Gaskill D K, Kazakova O 2015 ACS Nano 9 8401

Google Scholar

Google Scholar

[18] Lee C, Li Q Y, Kalb W, Liu X Z, Berger H, Carpick R W, Hone J 2010 Science 328 76

Google Scholar

Google Scholar

[19] Gong P, Li Q Y, Liu X Z, Carpick R W, Egberts P 2017 Tribol. Lett. 65 61

Google Scholar

Google Scholar

[20] Smolyanitsky A, Killgore J P, Tewary V K 2012 Phys. Rev. B 85 035412

Google Scholar

Google Scholar

[21] Li S Z, Li Q Y, Carpick R W, Gumbsch P, Liu X Z, Ding X D, Sun J, Li J 2016 Nature 539 541

Google Scholar

Google Scholar

[22] Schniepp H C, Kudin K N, Li J L, Prud'homme R K, Car R, Saville D A, Aksay I A 2008 ACS Nano 2 2577

Google Scholar

Google Scholar

[23] Zeng X Z, Peng Y T, Yu M C, Lang H J, Cao X A, Zou K 2018 ACS Appl. Mater. Interfaces 10 8214

Google Scholar

Google Scholar

[24] Li J J, Gao T Y, Luo J B 2018 Adv. Sci. 5 1700616

Google Scholar

Google Scholar

[25] Liu S W, Wang H P, Xu Q, Ma T B, Yu G, Zhang C, Geng D, Yu Z, Zhang S, Wang W, Hu Y Z, Wang H, Luo J 2017 Nat. Commun. 8 14029

Google Scholar

Google Scholar

[26] Cho D H, Wang L, Kim J S, Lee G H, Kim E S, Lee S, Lee S Y, Hone J, Lee C 2013 Nanoscale 5 3063

Google Scholar

Google Scholar

-

图 4 针尖测量历史对粘附力影响 (a)各区域粘附力变化图; (b)二氧化硅小球针尖SEM图; (c)二氧化硅小球针尖摩擦前粘附力变化图; (d)二氧化硅小球针尖摩擦前后粘附力

Fig. 4. The influence of tip measurement history on adhesion: (a) Change in adhesion of each region; (b) SEM image of silica ball tip; (c) change in adhesion of silica ball tip before rubbing; (d) adhesion before and after silica ball tip rubbing.

图 5 新鲜折叠石墨烯的产生与摩擦性能 (a)−(c)折叠前的形貌图、摩擦力全图、红线处的高度图和摩擦信号图; (d)−(f)折叠后的形貌图、摩擦力全图、红线处的高度图和摩擦信号图

Fig. 5. Production and tribological properties of freshly folded graphene: Morphology image, full view of friction, height and friction signal images at red line before folding (a)−(c) and after folding (d)−(f).

-

[1] Novoselov K S, Geim A K, Morozov S V, Jiang D, Zhang Y, Dubonos S V, Grigorieva I V, Firsov A A 2004 Science 306 666

Google Scholar

Google Scholar

[2] Zang X, Zhou Q, Chang J, Liu Y, Lin L 2015 Microelectron. Eng. 132 192

Google Scholar

Google Scholar

[3] Banhart F, Kotakoski J, Krasheninnikov A V 2011 ACS Nano 5 26

Google Scholar

Google Scholar

[4] Deng S K, Berry V 2016 Mater. Today 19 197

Google Scholar

Google Scholar

[5] Vasic B, Zurutuza A, Gajic R 2016 Carbon 102 304

Google Scholar

Google Scholar

[6] 覃业宏, 唐超, 张春小, 孟利军, 钟建新 2015 64 016804

Google Scholar

Google Scholar

Qin Y H, Tang C, Zhang C X, Meng L J, Zhong J X 2015 Acta Phys. Sin. 64 016804

Google Scholar

Google Scholar

[7] Yi H, Zhang X, Zhao Y, Liu Y, Song S 2017 J. Colloid Interface. Sci. 499 62

Google Scholar

Google Scholar

[8] Gajurel P, Kim M, Wang Q, Dai W T, Liu H T, Cen C 2017 Adv. Funct. Mater. 27 8

[9] Zheng F, Duan F L 2019 Tribol. Int. 134 87

Google Scholar

Google Scholar

[10] Kavalur A, Kim W K 2017 Comput. Mater. Sci. 137 346

Google Scholar

Google Scholar

[11] Tripathi M, Awaja F, Bizao R A, Signetti S, Iacob E, Paolicelli G, Valeri S, Dalton A, Pugno N M 2018 ACS Appl. Mater. Interfaces 10 44614

Google Scholar

Google Scholar

[12] Long F, Yasaei P, Yao W T, Salehi-Khojin A, Shahbazian-Yassar R 2017 ACS Appl. Mater. Interfaces 9 20922

Google Scholar

Google Scholar

[13] Hutter J L, Bechhoefer J 1993 Rev. Sci. Instrum. 64 1868

Google Scholar

Google Scholar

[14] Varenberg M, Etsion I, Halperin G 2003 Rev. Sci. Instrum. 74 3362

Google Scholar

Google Scholar

[15] Butt H J, Cappella B, Kappl M 2005 Surf. Sci. Rep. 59 1

Google Scholar

Google Scholar

[16] Farshchi-Tabrizi M, Kappl M, Cheng Y, Gutmann J, Butt H J 2006 Langmuir 22 2171

Google Scholar

Google Scholar

[17] Munz M, Giusca C E, Myers-Ward R L, Gaskill D K, Kazakova O 2015 ACS Nano 9 8401

Google Scholar

Google Scholar

[18] Lee C, Li Q Y, Kalb W, Liu X Z, Berger H, Carpick R W, Hone J 2010 Science 328 76

Google Scholar

Google Scholar

[19] Gong P, Li Q Y, Liu X Z, Carpick R W, Egberts P 2017 Tribol. Lett. 65 61

Google Scholar

Google Scholar

[20] Smolyanitsky A, Killgore J P, Tewary V K 2012 Phys. Rev. B 85 035412

Google Scholar

Google Scholar

[21] Li S Z, Li Q Y, Carpick R W, Gumbsch P, Liu X Z, Ding X D, Sun J, Li J 2016 Nature 539 541

Google Scholar

Google Scholar

[22] Schniepp H C, Kudin K N, Li J L, Prud'homme R K, Car R, Saville D A, Aksay I A 2008 ACS Nano 2 2577

Google Scholar

Google Scholar

[23] Zeng X Z, Peng Y T, Yu M C, Lang H J, Cao X A, Zou K 2018 ACS Appl. Mater. Interfaces 10 8214

Google Scholar

Google Scholar

[24] Li J J, Gao T Y, Luo J B 2018 Adv. Sci. 5 1700616

Google Scholar

Google Scholar

[25] Liu S W, Wang H P, Xu Q, Ma T B, Yu G, Zhang C, Geng D, Yu Z, Zhang S, Wang W, Hu Y Z, Wang H, Luo J 2017 Nat. Commun. 8 14029

Google Scholar

Google Scholar

[26] Cho D H, Wang L, Kim J S, Lee G H, Kim E S, Lee S, Lee S Y, Hone J, Lee C 2013 Nanoscale 5 3063

Google Scholar

Google Scholar

计量

- 文章访问数: 7920

- PDF下载量: 120

- 被引次数: 0

下载:

下载: