-

为了探索微/纳米粒子的散射特性, 提出采用贝塞尔光束悬浮和散射测量耦合的方法搭建悬浮散射测试系统装置, 对单颗微米粒子/纳米团簇的散射强度分布进行精确测量. 首先利用两束反向传输的贝塞尔光束对多种类型和尺寸的粒子/团簇进行悬浮, 判定粒子的悬浮稳定性; 然后对悬浮粒子以9.2'' 的角分辨率在平面2π角度内的散射强度分布进行测量. 模拟计算了激光作用下粒子的受力以及不同参数粒子的散射强度分布, 并与实验结果进行对比, 深入地分析了环境因素对散射测试系统不确定度的干扰程度, 详细讨论了悬浮不稳定性对散射测量结果的影响. 研究结果表明, 反向传输的贝塞尔光束可对金属镁、铝和石墨等粒子/团簇进行稳定悬浮, 其相对不稳定度小于0.15, 悬浮过程中光泳力起主导作用; 单颗微米粒子/纳米团簇的散射强度分布符合Mie粒子散射特征, 折射率虚部大的粒子具有更强的前向散射特性, 粒子尺寸参数越大, 则前向散射作用越强. 单颗微粒散射强度分布的精确测量证实了悬浮散射测试系统的通用性和可靠性, 为深入认识物质散射特性提供了一种新的研究手段.The scattering measurement of particulates in gaseous medium is helpful in understanding light transmission, laser detection, combustion radiation and atmospheric environment. In order to explore the scattering characteristics of micron-/nano-sized particles, this paper proposes a method of accurately measuring the scattering intensity distribution of a single micron-sized particles/nanoclusters by combining laser levitation and scattering measurement. An experimental apparatus is first built based on the counter-propagated bi-Bessel beams levitation system and scattering test system. The microparticles/nanoclusters of various matters and sizes are then levitated and their stabilities are evaluated. Finally, the scattering intensity distribution of levitated particles within 2π scattering angle is accurately measured with an angular resolution of 9.2″. The forces acting on particles under laser irradiation and the scattering intensity distribution of different particle parameters are simulated and calculated, and compared with experimental results. The influence of noise on the uncertainty of the scattering measurement system is analyzed in depth, including background light, laser beam, and reflected light from the walls. The results show that the signal-to-noise ratio of scattering measurement for metallic magnesium and aluminum, whether single particles or clusters, are both greater than 20 dB and their maximum values are both 94.6 dB in a range of 2π angle. For graphite nanoclusters, the signal-to-noise ratio in the backscattering direction is relatively poor. The influence of levitation instability on the scattering measurement results is estimated in detail, verifying that the influence of levitation instability in the test system on the scattering measurement is ignorable. Metallic magnesium, aluminum, and graphite particles can be stably levitated by the counter-propagated bi-Bessel beams, with a relative instability of less than 0.15. During the levitation, the photophoretic force plays a dominant role. The scattering intensity distribution of a single micron-sized particles and nanoclusters both conform to the scattering characteristics of Mie particles. Microparticles with large refractive index imaginary parts have stronger forward scattering characteristics. The larger the particle size parameter, the stronger the forward scattering effect becomes. The accurate measurement of the scattering intensity distribution of a single microparticles confirms the versatility and reliability of the levitation scattering test system, providing a new research method for in-depth understanding of the scattering characteristics of substances.

-

Keywords:

- laser levitation /

- Mie scattering /

- individual microparticle /

- nanocluster

[1] Sioutas C, Kim S, Chang M, Terrell L L, Gong H 2000 Atmos. Environ. 34 4829

Google Scholar

Google Scholar

[2] Zhang H, Nie W, Liang Y, Chen J, Peng H 2021 Opt. Laser. Eng. 144 106642

Google Scholar

Google Scholar

[3] Minton A P 2016 Anal. Biochem. 501 4

Google Scholar

Google Scholar

[4] 张宇微, 颜燕, 农大官, 徐春华, 李明 2016 65 218702

Google Scholar

Google Scholar

Zhang Y W, Yan Y, Nong D G, Xu C H, Li M 2016 Acta Phys. Sin. 65 218702

Google Scholar

Google Scholar

[5] 王清华, 张颖颖, 来建成, 李振华, 贺安之 2007 56 1203

Google Scholar

Google Scholar

Wang Q H, Zhang Y Y, Lai J C, Li Z H, He A Z 2007 Acta Phys. Sin. 56 1203

Google Scholar

Google Scholar

[6] Collins M, Kauppila A, Karmenyan A, Gajewski L, Szewczyk K, Kinnunen M, Myllylä R 2010 Laser Applications in Life Sciences Oulu, Finland, June 9–11, 2010 p737619

[7] Ashkin A 1970 Phys. Rev. Lett. 24 156

Google Scholar

Google Scholar

[8] Omori R, Kobayashi T, Suzuki A 1997 Opt. Lett. 22 816

Google Scholar

Google Scholar

[9] Esseling M, Rose P, Alpmann C, Denz C 2012 Appl. Phys. Lett. 101 131

[10] Huisken J, Stelzer E H K 2002 Opt. Lett. 27 1223

Google Scholar

Google Scholar

[11] Meresman H, Wills J B, Summers M, McGloin D, Reid J P 2009 Phys. Chem. Chem. Phys. 11 11333

Google Scholar

Google Scholar

[12] Pan Y L, Hill S C, Coleman M 2012 Opt. Express 20 5325

Google Scholar

Google Scholar

[13] Gong Z, Pan Y L, Wang C 2016 Rev. Sci. Instrum. 87 156

[14] Gong Z, Pan Y L, Videen G, Wang C 2017 Chem. Phys. Lett. 689 100

Google Scholar

Google Scholar

[15] 黄雪峰, 李盛姬, 周东辉, 赵冠军, 王关晴, 徐江荣 2014 63 178802

Google Scholar

Google Scholar

Huang X F, Li S J, Zhou D H, Zhao G J, Wang G Q, Xu J R 2014 Acta Phys. Sin. 63 178802

Google Scholar

Google Scholar

[16] Grehan G, Gouesbet G 1980 Appl. Opt. 19 2485

Google Scholar

Google Scholar

[17] 付成花 2017 66 097301

Google Scholar

Google Scholar

Fu C H 2017 Acta Phys. Sin. 66 097301

Google Scholar

Google Scholar

[18] Gouesbet G 2019 J. Quant. Spectrosc. Radiat. Transfer 225 258

Google Scholar

Google Scholar

[19] Misconi N Y, Oliver J P, Ratcliff K F, Rusk E T, Wang W X 1990 Appl. Opt. 29 2276

Google Scholar

Google Scholar

[20] Nieminen T A, Loke V L Y, Stilgoe A B, Knöner G, Brańczyk A M, Heckenberg N R, Rubinsztein-Dunlop H 2007 J. Opt. A: Pure Appl. Opt. 9 S196

Google Scholar

Google Scholar

[21] Palm K J, Murray J B, Narayan T C, Munday J N 2018 ACS Photonics 5 4677

Google Scholar

Google Scholar

[22] McPeak K M, Jayanti S V, Kress S J, Meyer S, Iotti S, Rossinelli A, Norris D J 2015 ACS Photonics 2 326

Google Scholar

Google Scholar

[23] Querry M R 1985 Optical Constants Contractor Report CRDCCR-85034

[24] Mackowski D W 1989 Int. J. Heat Mass Transfer. 32 843

Google Scholar

Google Scholar

[25] Talbot L, Cheng R K, Schefer R W, Willis D R 1980 J. Fluid Mech. 101 737

Google Scholar

Google Scholar

[26] Redding B, Hill S C, Alexson D, Wang C, Pan Y L 2015 Opt. Express 23 3630

Google Scholar

Google Scholar

-

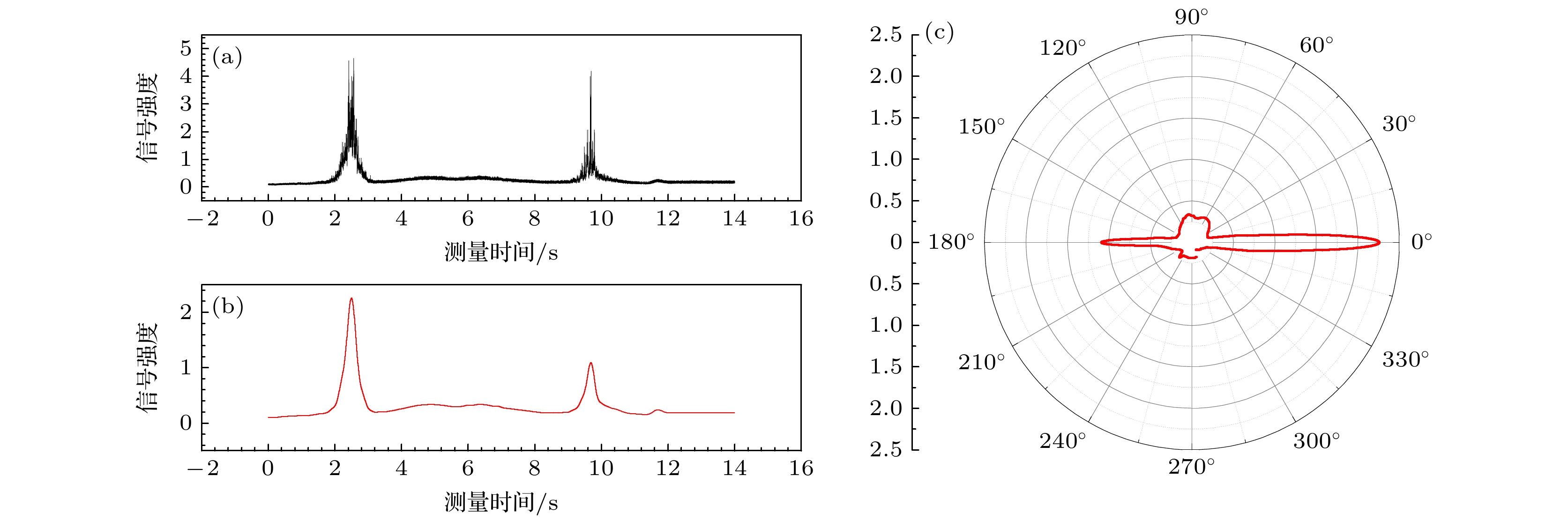

图 5 (a) 第一组镁粒子的悬浮图; (b) 第一组镁粒子的散射强度分布矢极图; (c) 第二组镁粒子的悬浮图; (d) 第二组镁粒子的散射强度分布矢极图

Fig. 5. (a) A picture of the first levitated Mg microparticle; (b) contour of scattering intensity distribution of the first levitated Mg microparticle in polar coordinates; (c) the picture of the second levitated Mg microparticle; (d) contour of scattering intensity distribution of the second levitated Mg microparticle in polar coordinates.

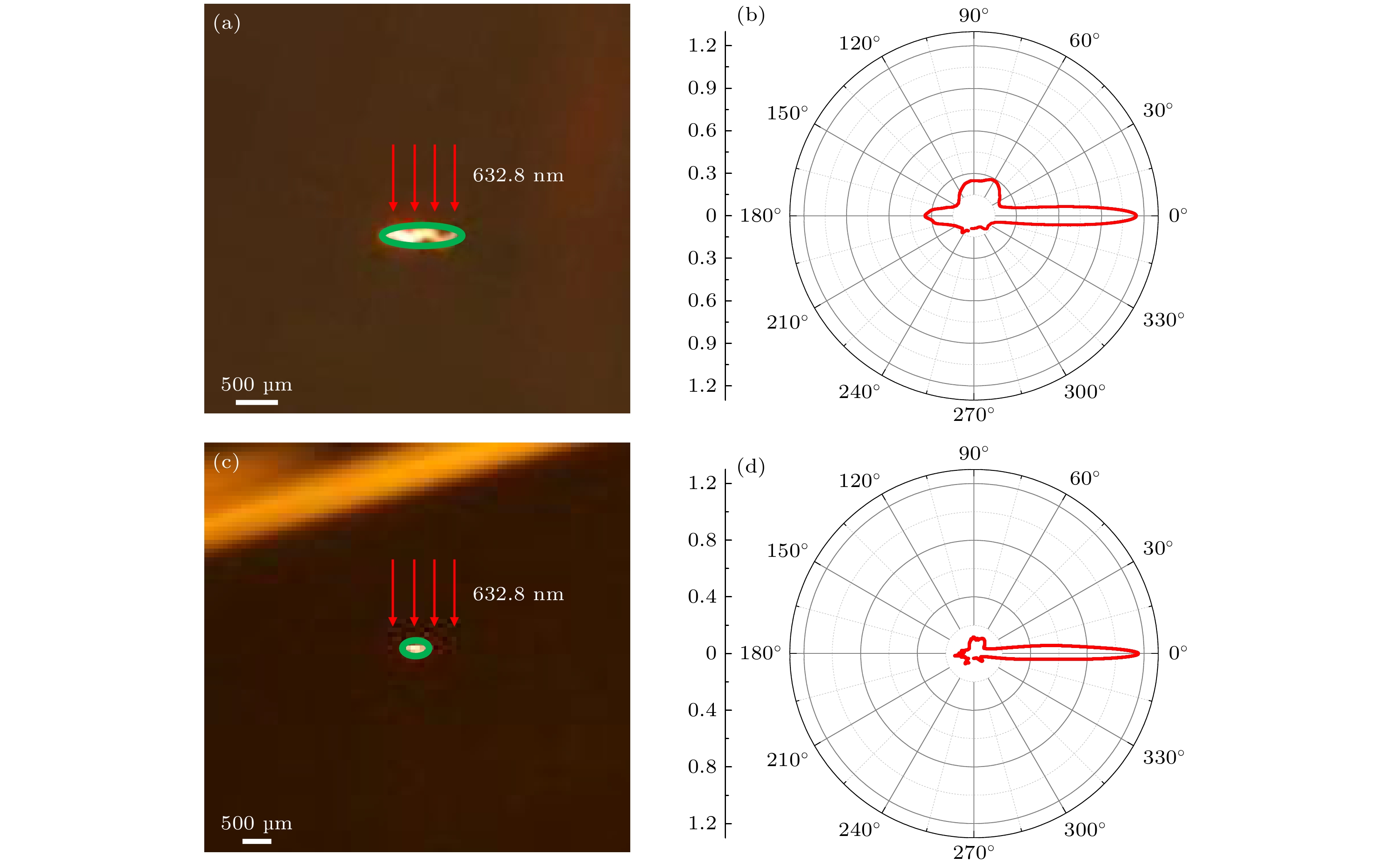

图 6 (a) 纳米铝团簇的悬浮图; (b) 纳米铝团簇的散射强度分布矢极图; (c) 纳米石墨团簇的悬浮图; (d) 纳米石墨团簇的散射强度分布矢极图

Fig. 6. (a) The picture of levitated Al nanocluster; (b) contour of scattering intensity distribution of levitated Al nanocluster in polar coordinates; (c) the picture of levitated graphite nanocluster; (d) contour of scattering intensity distribution of levitated graphite nanocluster in polar coordinates.

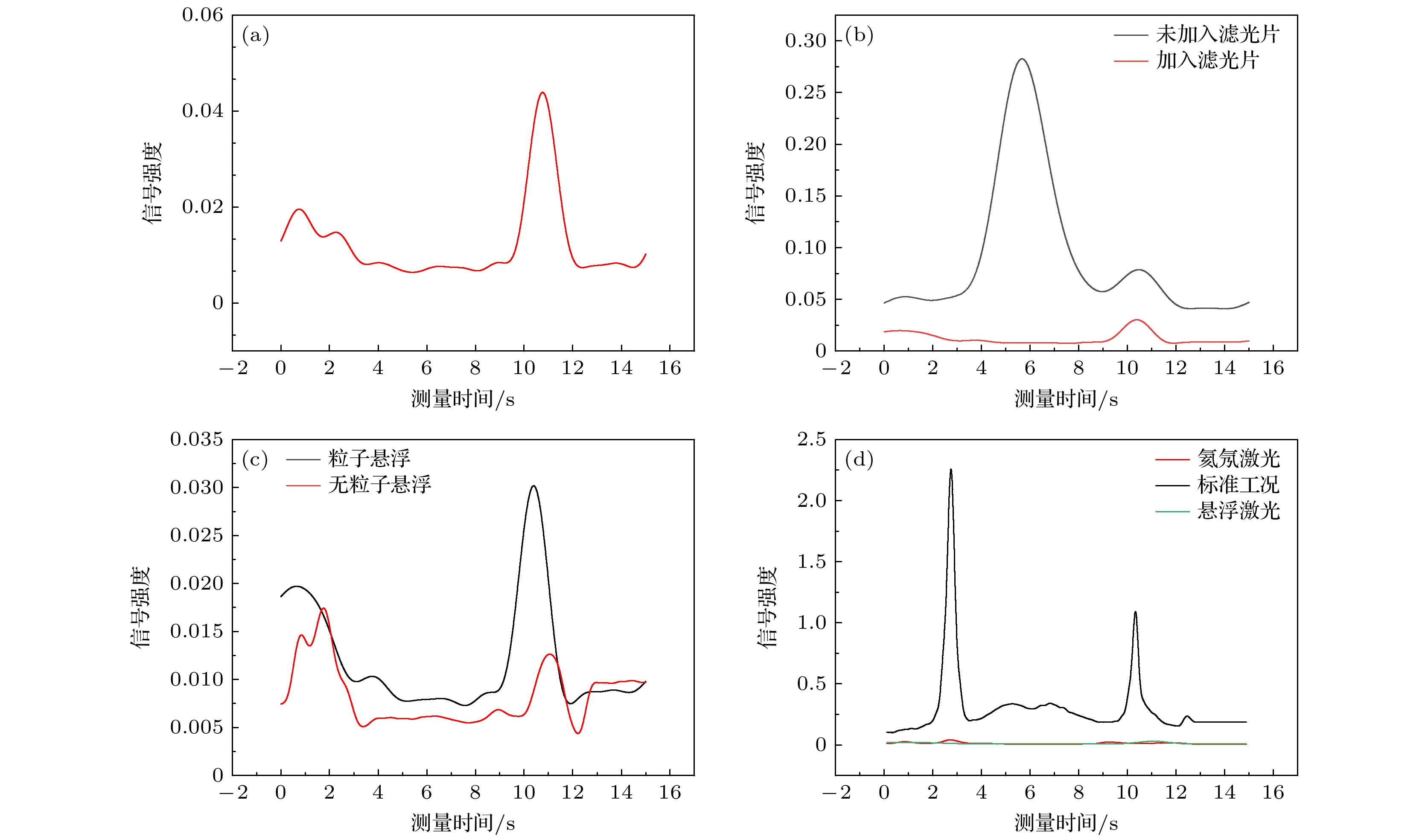

图 9 (a) 环境光信号; (b) 加入滤光片前后悬浮激光散射信号; (c) 粒子悬浮前后悬浮激光散射信号; (d) 标准工况下散射信号与其他信号

Fig. 9. (a) Signal from background light; (b) laser scattering signals adding filters or not; (c) laser scattering signals of levitated microparticle or not; (d) scattering signals and other signals under standard operating conditions.

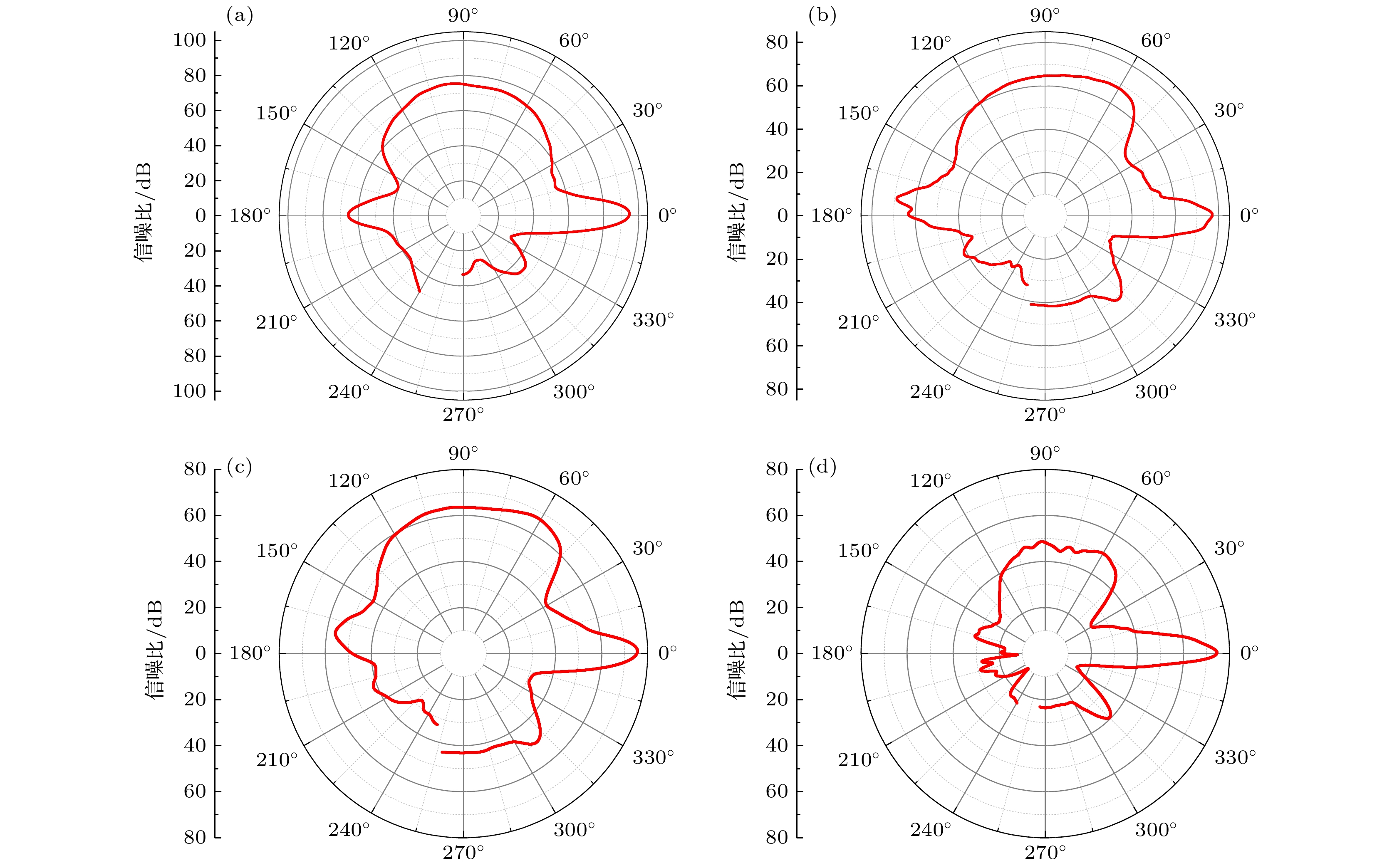

图 10 散射强度测量信噪比矢极图 (a) 第一组镁粒子; (b) 第二组镁粒子; (c) 纳米铝团簇; (d) 纳米石墨团簇

Fig. 10. Contour of signal-to-noise ratio of scattering intensity measurement in polar coordinates: (a) The first levitated Mg microparticle; (b) the second levitated Mg microparticle; (c) levitated Al nanocluster; (d) levitated graphite nanocluster.

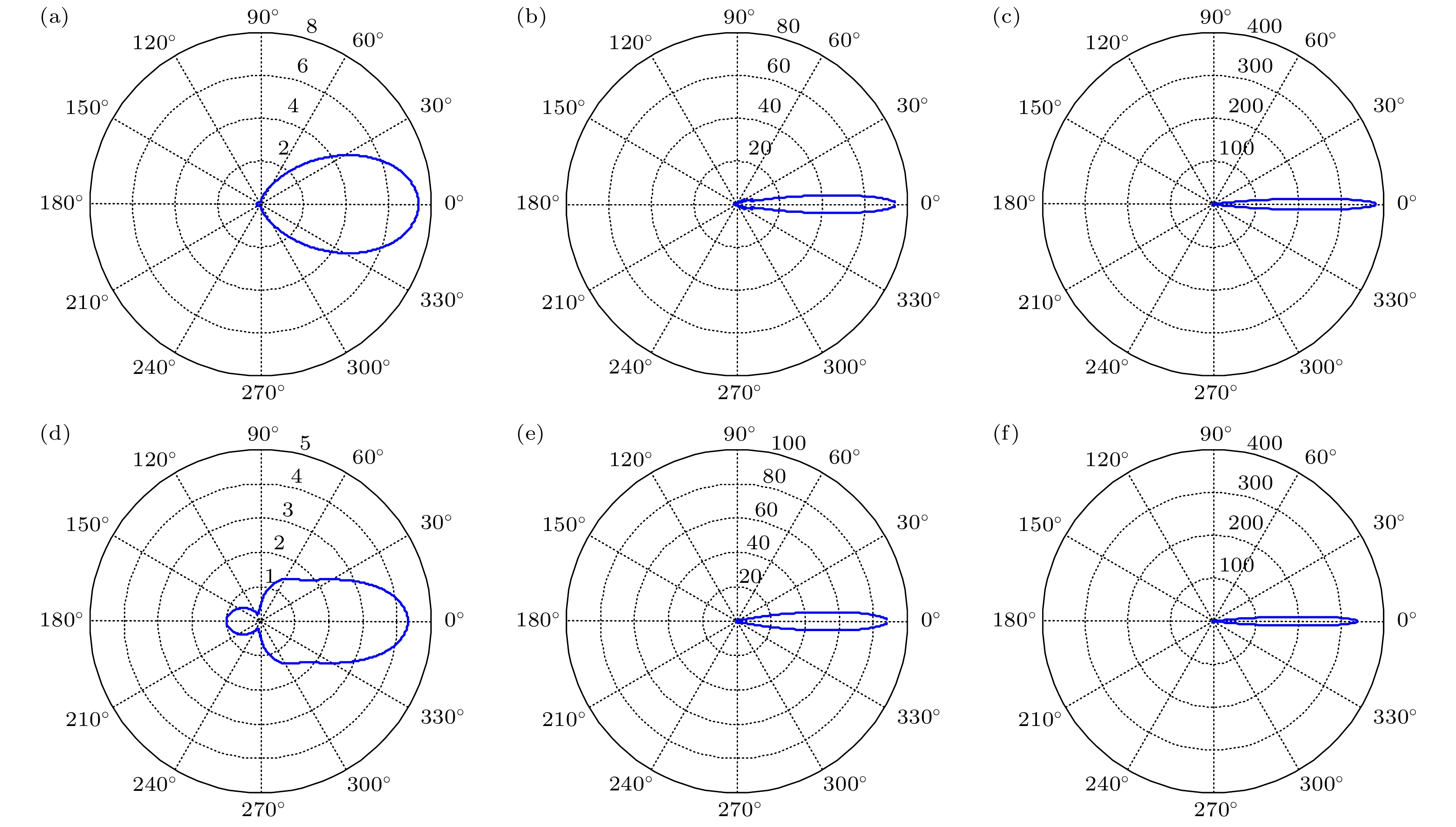

图 12 不同尺寸参数对散射强度的影响 (a) α = 2.5 (水); (b) α = 12.5 (水); (c) α = 25 (水); (d) α = 2.5 (Mg); (e) α = 12.5 (Mg); (f) α = 25 (Mg)

Fig. 12. Effect of different size parameters on scattering intensity: (a) α = 2.5 (water); (b) α = 12.5 (water); (c) α = 25 (water); (d) α = 2.5 (Mg); (e) α = 12.5 (Mg); (f) α = 25 (Mg).

表 1 金属镁、铝和石墨粒子受激光作用时的光泳力和辐射压力

Table 1. Photophorestic force and radiation pressure of Mg, Al, and graphite microparticles exerted by the laser beam.

-

[1] Sioutas C, Kim S, Chang M, Terrell L L, Gong H 2000 Atmos. Environ. 34 4829

Google Scholar

Google Scholar

[2] Zhang H, Nie W, Liang Y, Chen J, Peng H 2021 Opt. Laser. Eng. 144 106642

Google Scholar

Google Scholar

[3] Minton A P 2016 Anal. Biochem. 501 4

Google Scholar

Google Scholar

[4] 张宇微, 颜燕, 农大官, 徐春华, 李明 2016 65 218702

Google Scholar

Google Scholar

Zhang Y W, Yan Y, Nong D G, Xu C H, Li M 2016 Acta Phys. Sin. 65 218702

Google Scholar

Google Scholar

[5] 王清华, 张颖颖, 来建成, 李振华, 贺安之 2007 56 1203

Google Scholar

Google Scholar

Wang Q H, Zhang Y Y, Lai J C, Li Z H, He A Z 2007 Acta Phys. Sin. 56 1203

Google Scholar

Google Scholar

[6] Collins M, Kauppila A, Karmenyan A, Gajewski L, Szewczyk K, Kinnunen M, Myllylä R 2010 Laser Applications in Life Sciences Oulu, Finland, June 9–11, 2010 p737619

[7] Ashkin A 1970 Phys. Rev. Lett. 24 156

Google Scholar

Google Scholar

[8] Omori R, Kobayashi T, Suzuki A 1997 Opt. Lett. 22 816

Google Scholar

Google Scholar

[9] Esseling M, Rose P, Alpmann C, Denz C 2012 Appl. Phys. Lett. 101 131

[10] Huisken J, Stelzer E H K 2002 Opt. Lett. 27 1223

Google Scholar

Google Scholar

[11] Meresman H, Wills J B, Summers M, McGloin D, Reid J P 2009 Phys. Chem. Chem. Phys. 11 11333

Google Scholar

Google Scholar

[12] Pan Y L, Hill S C, Coleman M 2012 Opt. Express 20 5325

Google Scholar

Google Scholar

[13] Gong Z, Pan Y L, Wang C 2016 Rev. Sci. Instrum. 87 156

[14] Gong Z, Pan Y L, Videen G, Wang C 2017 Chem. Phys. Lett. 689 100

Google Scholar

Google Scholar

[15] 黄雪峰, 李盛姬, 周东辉, 赵冠军, 王关晴, 徐江荣 2014 63 178802

Google Scholar

Google Scholar

Huang X F, Li S J, Zhou D H, Zhao G J, Wang G Q, Xu J R 2014 Acta Phys. Sin. 63 178802

Google Scholar

Google Scholar

[16] Grehan G, Gouesbet G 1980 Appl. Opt. 19 2485

Google Scholar

Google Scholar

[17] 付成花 2017 66 097301

Google Scholar

Google Scholar

Fu C H 2017 Acta Phys. Sin. 66 097301

Google Scholar

Google Scholar

[18] Gouesbet G 2019 J. Quant. Spectrosc. Radiat. Transfer 225 258

Google Scholar

Google Scholar

[19] Misconi N Y, Oliver J P, Ratcliff K F, Rusk E T, Wang W X 1990 Appl. Opt. 29 2276

Google Scholar

Google Scholar

[20] Nieminen T A, Loke V L Y, Stilgoe A B, Knöner G, Brańczyk A M, Heckenberg N R, Rubinsztein-Dunlop H 2007 J. Opt. A: Pure Appl. Opt. 9 S196

Google Scholar

Google Scholar

[21] Palm K J, Murray J B, Narayan T C, Munday J N 2018 ACS Photonics 5 4677

Google Scholar

Google Scholar

[22] McPeak K M, Jayanti S V, Kress S J, Meyer S, Iotti S, Rossinelli A, Norris D J 2015 ACS Photonics 2 326

Google Scholar

Google Scholar

[23] Querry M R 1985 Optical Constants Contractor Report CRDCCR-85034

[24] Mackowski D W 1989 Int. J. Heat Mass Transfer. 32 843

Google Scholar

Google Scholar

[25] Talbot L, Cheng R K, Schefer R W, Willis D R 1980 J. Fluid Mech. 101 737

Google Scholar

Google Scholar

[26] Redding B, Hill S C, Alexson D, Wang C, Pan Y L 2015 Opt. Express 23 3630

Google Scholar

Google Scholar

计量

- 文章访问数: 6007

- PDF下载量: 279

- 被引次数: 0

下载:

下载: