-

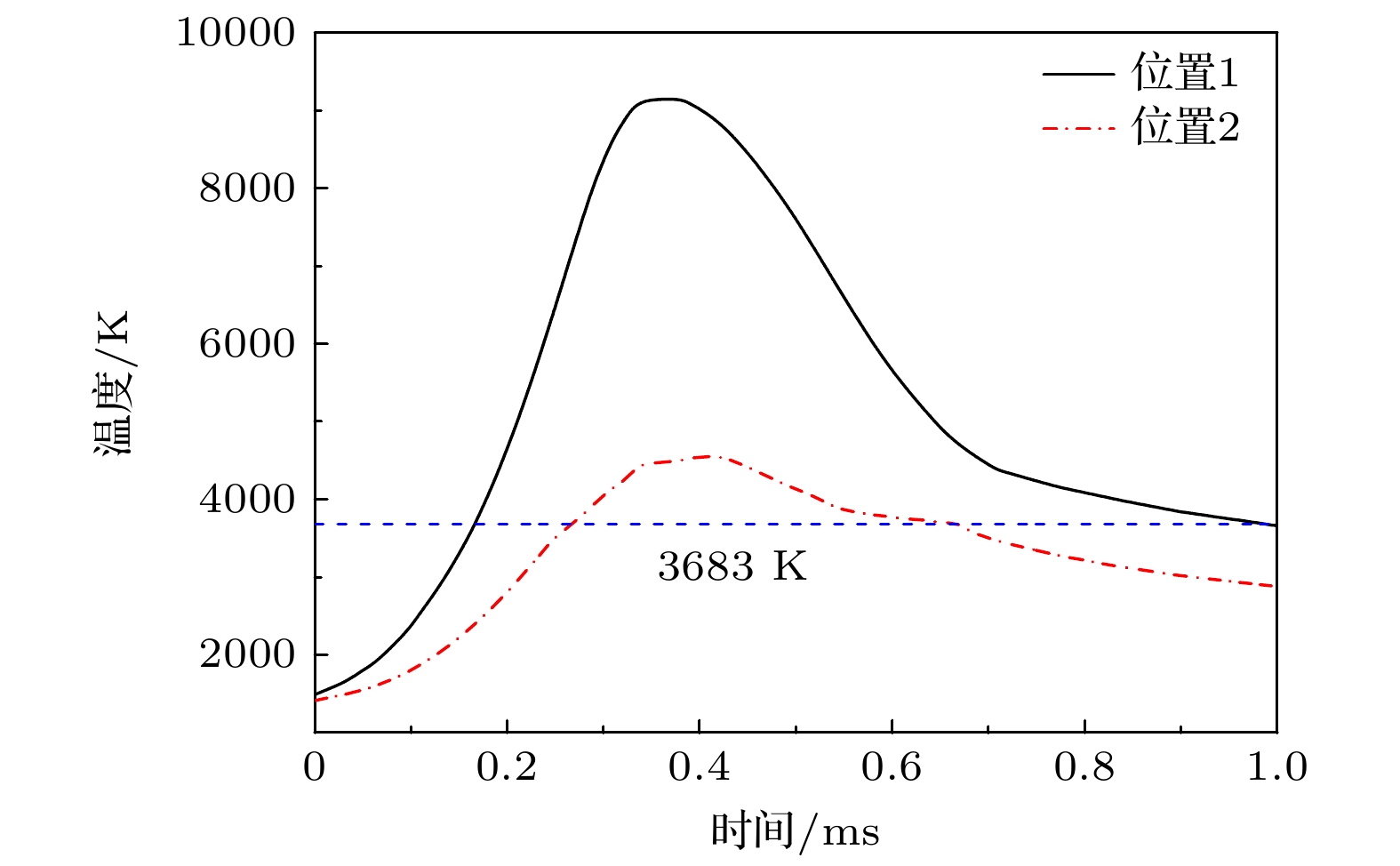

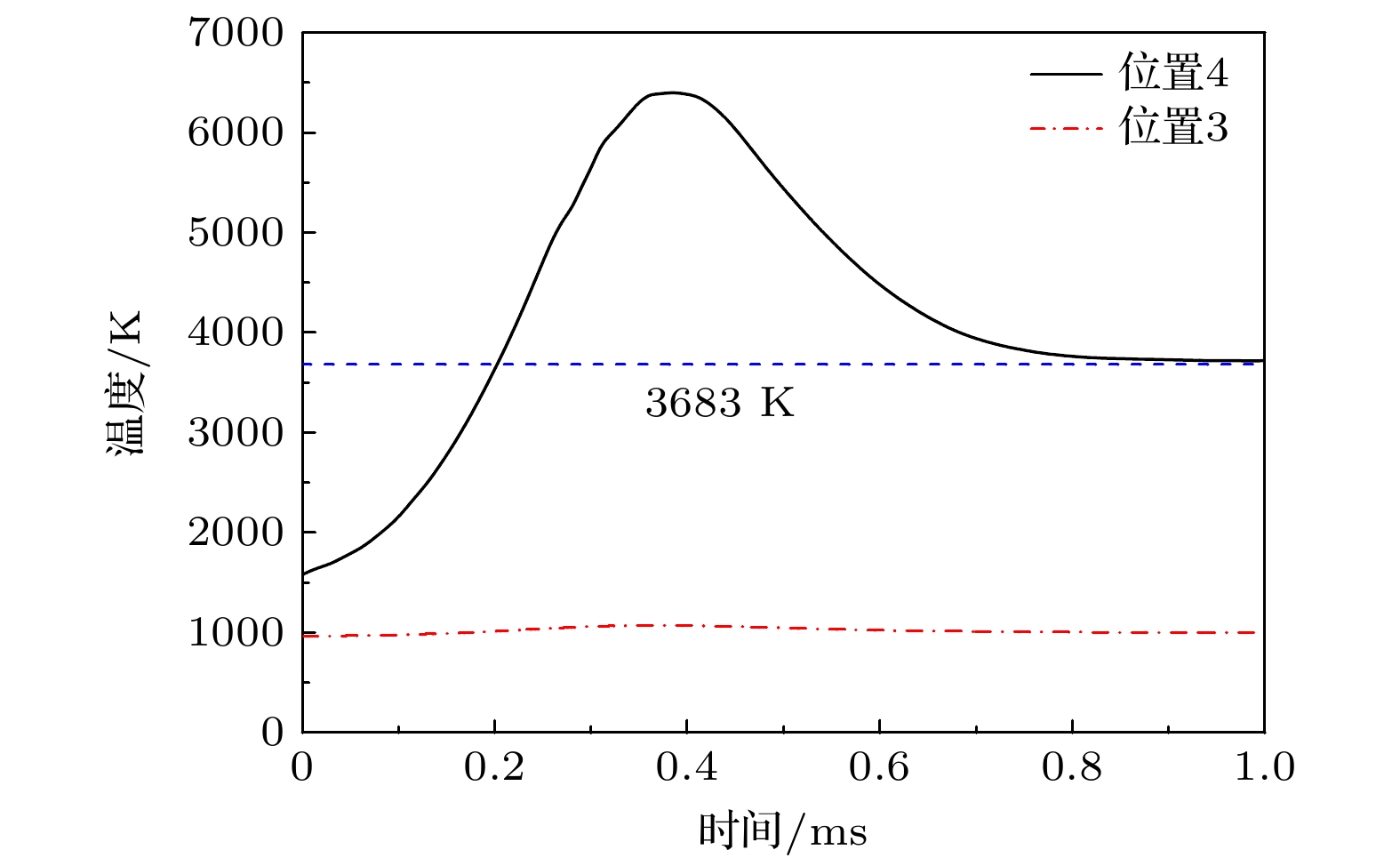

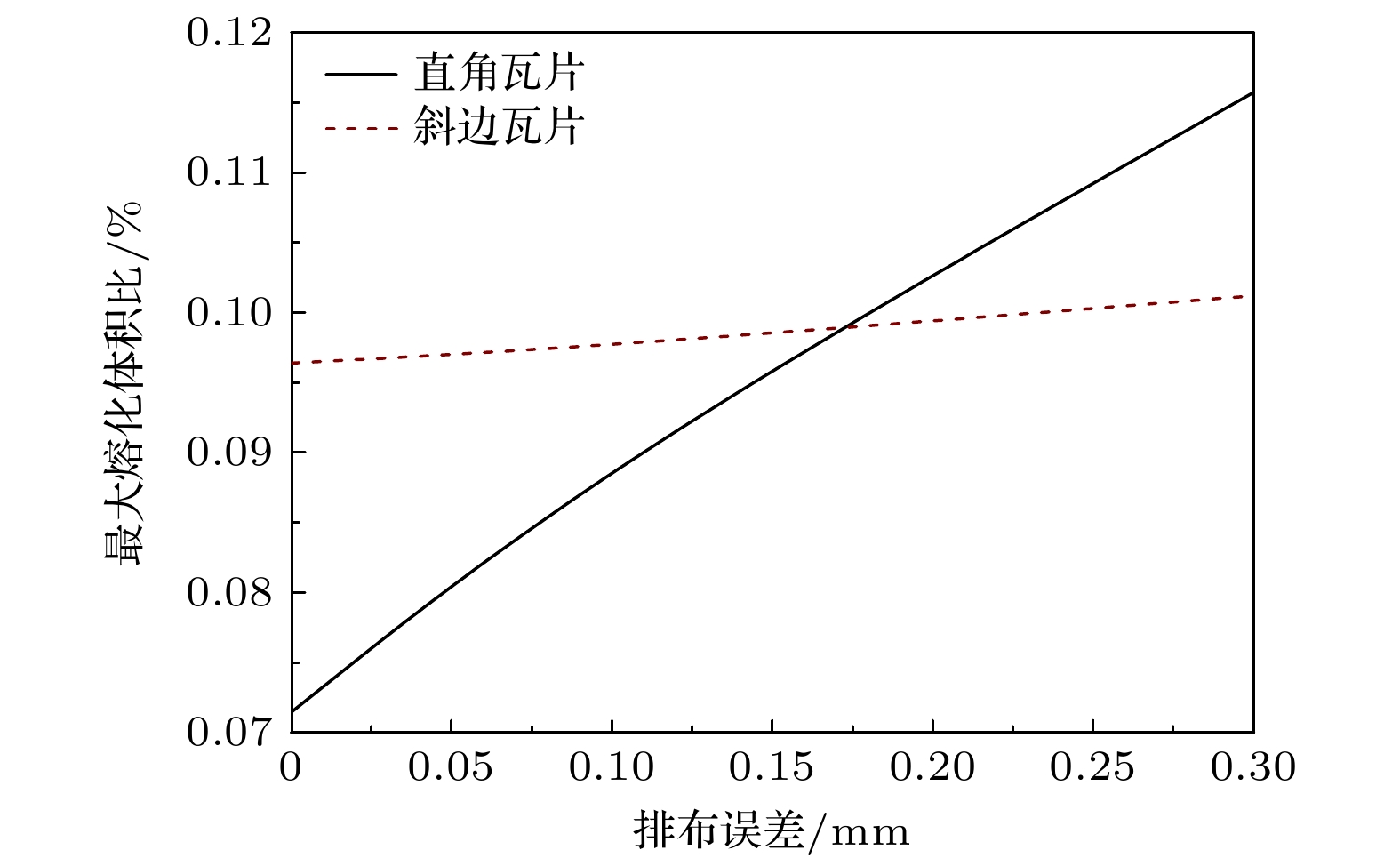

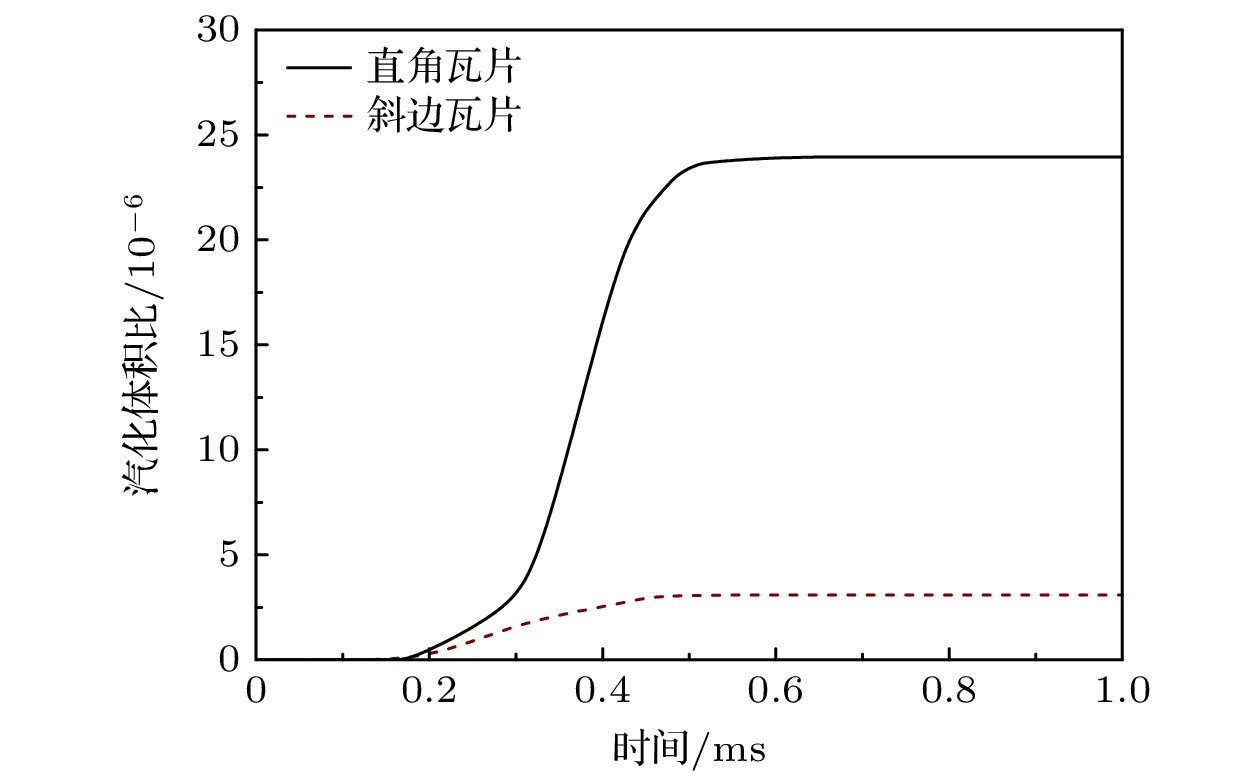

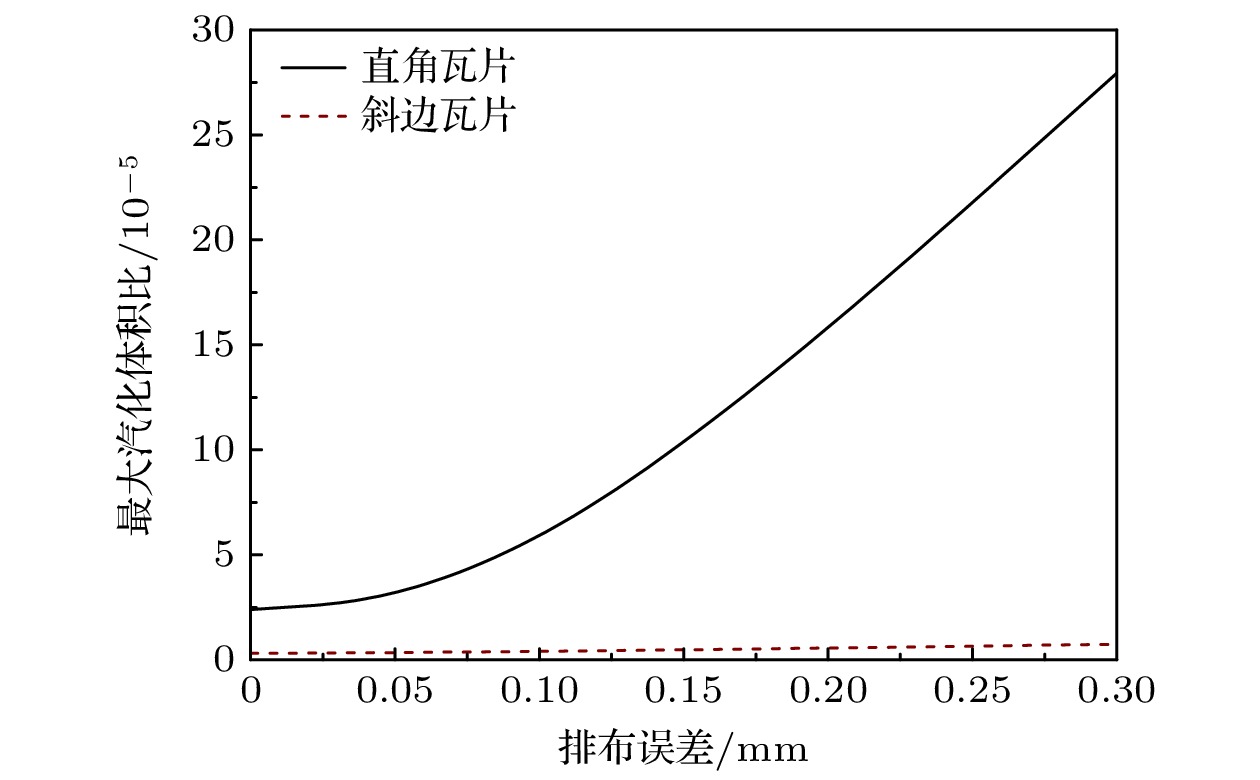

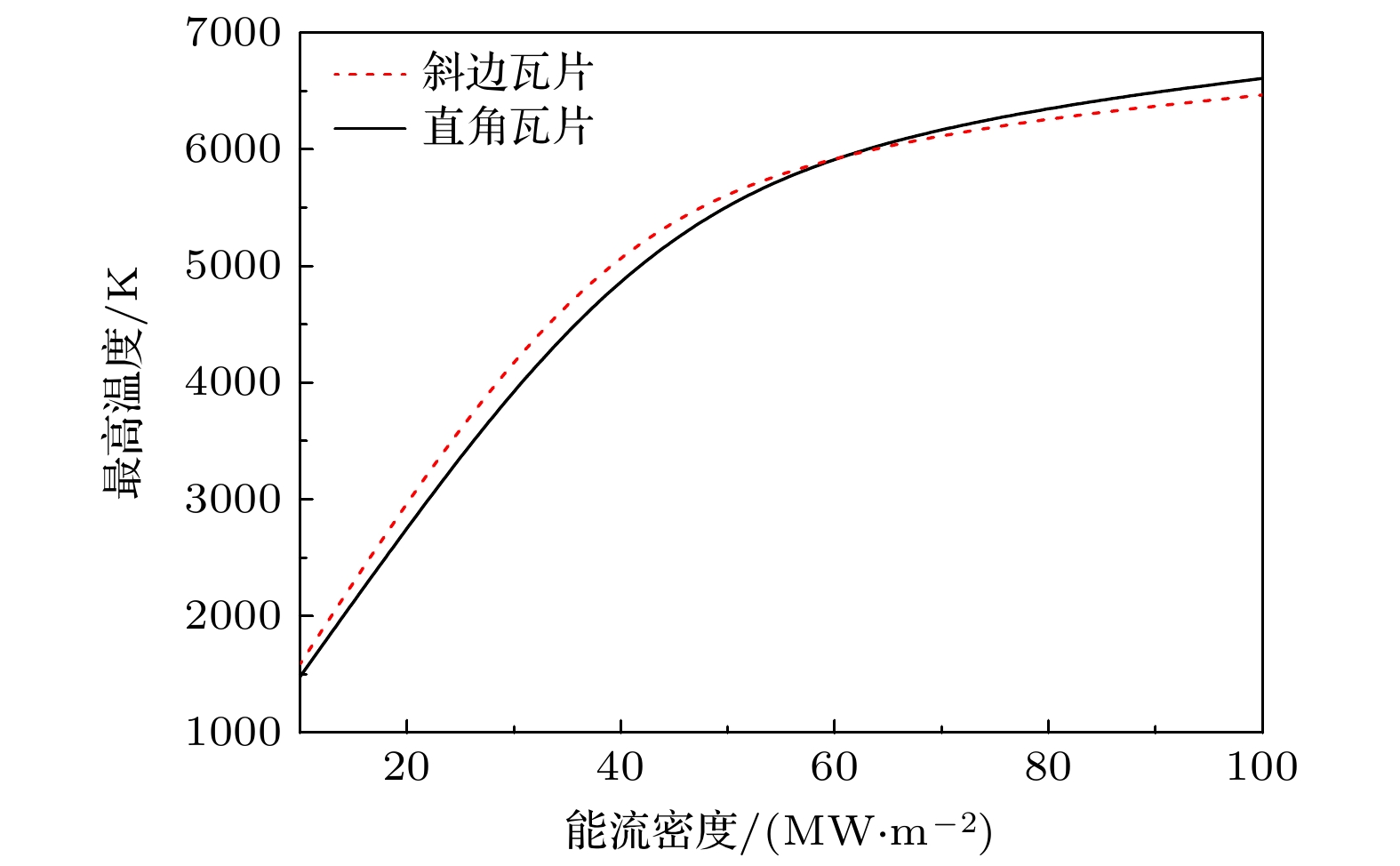

偏滤器靶板钨/铜瓦片在高热流作用下的热表现是未来托卡马克ITER最受关注的问题之一. 由于安装精度等因素, 钨/铜瓦片会出现排布位错从而产生凸出棱边, 凸出棱边处能流密度极大, 严重侵蚀靶板. 建立了二维对流传热的自洽模型, 包括热辐射、汽化和熔化效应, 同时, 耦合冷却水状态变化, 研究类ITER第一类边界局域模热流对出现排布位错的偏滤器靶板钨/铜瓦片的腐蚀程度, 比较直角、斜边瓦片的热性能. 为了研究瓦片缝隙、排布误差对等离子体行为和能流密度分布的影响, 利用二维边缘等离子体动理学程序计算不同排布误差下两种形状瓦片表面的能流密度分布, 并作为热传导模型的输入参数. 研究结果表明: 瓦片缝隙附近等离子体行为会受排布误差影响, 不同排布误差下的直角、斜边瓦片边缘处能流密度分布不同, 对两种形状瓦片的热表现影响极大, 排布误差越大, 两种形状瓦片的热腐蚀程度越大; 相对于直角瓦片, 斜边瓦片在边界局域模热流作用下的热腐蚀程度较小, 且有较好的对抗排布位错的能力.The thermal performance of the divertor W/Cu monoblock tiles under the ITER-like transient events has been one of the main concerns for ITER plasma facing components. Owing to the assembly tolerances during installation, the leading edge caused by misalignment between toroidal neighboring tiles will receive the extremely high cumulative heat flux and be damaged. In this work, we develop a two-dimensional heat conductivity model, including evaporation, radiation, melting process, and coupling cooling water condition, to investigate the thermal erosion of two shapes of tiles of W/Cu monoblock (unshaped and beveled tiles) with misalignment in a range from 0 to 0.3 mm, within the allowable maximum misalignment for ITER. To reflect the geometrical effects of castellated divertor tiles on the properties of its adjacent plasma, the energy flux density distribution arriving at the castellated divertor tile surface is evaluated first by using a two-dimension-in-space and three-dimension-in-velocity particle-in-cell plus Monte Carlo collisions code, and the obtained energy flux distribution is then used as input for the heat conduction model. The simulation results show that the maximum temperature of the unshaped tile with no misalignment is lower than that of the beveled tile under the steady-state inter-ELM heat flux, which increases more quickly than that of the beveled tile with misalignment increasing and will be larger than that of the beveled tile when misalignment is not less than 0.105 mm. Two shapes of the divertor tiles would melt and vaporize under typical heat flux density of a transient event of type-I edge localized modes (ELMs) for ITER, deposition energy of 1 MJ·m–2 in a duration of 600 μs. The highest temperature, the maximum melting thickness, the maximum vaporization thickness of the unshaped tile with no misalignment are higher than those of the beveled tile except the melting volume ratio. The thermal erosion of the unshaped tile increases more remarkably than that of the beveled tile with misalignment increasing, and the melting volume ratio of the unshaped tile will exceed that of the beveled tile at a misalignment of 0.17 mm. In comparison with the unshaped tile, the beveled tile is more resistant to such a high heat flux of an ELM and misalignment.

-

Keywords:

- edge localized modes /

- W/Cu monoblock /

- misalignment /

- thermal performance

[1] Federici G, Skinner C H, Brooks J N, Coad J P, Grisolia C, Haasz A A, Hassanein A, Philipps V, Pitcher C S, Roth J, Wampler W R, Whyte D G 2001 Nucl. Fusion 41 1967

Google Scholar

Google Scholar

[2] Bolt H, Barabash V, Krauss W, Linke J, Neu R, Suzuki S, Yoshida N, ASDEX Upgrade Team 2004 J. Nucl. Mater. 329–333 66

Google Scholar

Google Scholar

[3] Pitts R A, Bonnin X, Escourbiac F, Frerichs H, Gunn J P, Hirai T, Kukushkin A S, Kaveeva E, Miller M A, Moulton D, Rozhansk V Y, Senichenkov I, Sytova E, Schmitz O, Stangeby P C, De Temmerman G, Veselova I, Wiesen S 2019 Nucl. Mater. Energy 20 100696

Google Scholar

Google Scholar

[4] Wang B G, Zhu D Z, Ding R, Chen J L 2017 Plasma Sci. Technol. 19 025603

Google Scholar

Google Scholar

[5] Hirai T, Escourbiac F, Carpentier-Chouchana S, Fedosov A, Ferrand L, Jokinen T, Komarov V, Kukushkin A, Merola M, Mitteau R, Pitts R A, Shu W, Sugihara M, Riccardi B, Suzuki S, Villari R 2013 Fusion Eng. Des. 88 1798

Google Scholar

Google Scholar

[6] Missirlian M, Firdaouss M, Richou M, Languille P, Lecocq S, Lipa M 2013 Fusion Eng. Des. 88 1793

Google Scholar

Google Scholar

[7] Li C J, Zhu D Z, Ding R, Wang B G, Chen J L, Gao B F, Le Y 2020 Nucl. Mater. Energy 25 100847

Google Scholar

Google Scholar

[8] Perkins F W, Post D E, Uckan N A, et al. 1999 Nucl. Fusion 39 2137

Google Scholar

Google Scholar

[9] Loarte A, Saibene G, Sartori R, Riccardo V, Andrew P, Paley J, Fundamenski W, Eich T, Herrmann A, Pautasso G, Kirk A, Counsell G, Federici G, Strohmayer G, Whyte D, Leonard A, Pitts R A, Landman I, Bazylev B, Pestchanyi S 2007 Phys. Scr. T128 222

Google Scholar

Google Scholar

[10] Bazylev B, Janeschitz G, Landman I S, Loarte A, Pestchanyi S E 2007 J. Nucl. Mater. 363–365 1011

Google Scholar

Google Scholar

[11] Bazylev B, Janeschitz G, Landman I S, Pestchanyi S E 2005 Fusion Eng. Des. 75–79 407

Google Scholar

Google Scholar

[12] Coenen J W, Bazylev B, Brezinsek S, Philipps V, Hirai T, Kreter A, Linke J, Sergienko G, Pospieszczyk A, Tanabe T, Ueda Y, Samm U, The TEXTOR-Team 2011 J. Nucl. Mater. 415 S78

Google Scholar

Google Scholar

[13] Chen X H, Ding F, Mao H M, Luo G N, Hu Z H, Xu F, Niu G J 2016 Fusion Eng. Des.108 98

Google Scholar

Google Scholar

[14] El-Din El-Morshedy S 2021 Nucl. Mater. Energy 28 101035

Google Scholar

Google Scholar

[15] Raffray A R, Federici G J 1997 Nucl. Mater. 244 85

Google Scholar

Google Scholar

[16] Federici G, Loarte A, Strohmayer G 2003 Plasma Phys. Control. Fusion 45 1523

Google Scholar

Google Scholar

[17] Dejarnac R, Gunn J P 2007 J. Nucl. Mater. 363–365 560

Google Scholar

Google Scholar

[18] Gunn J P, Carpentier S C, Dejarnac R, Escourbiac F, Hirai T, Komm M, Kukushkin A, Panayotis S, Pitts R A 2016 Nucl. Mater. Energ. 12 75

Google Scholar

Google Scholar

[19] Gunn J P, Carpentier-Chouchana S, Escourbiac F, Hirai T, Panayotis S, Pitts R A, Corre Y, Dejarnac R, Firdaouss M, Kočan M, Komm M, Kukushkin A, Languille P, Missirlian M, Zhao W, Zhong G 2017 Nucl. Fusion 57 046025

Google Scholar

Google Scholar

[20] Komm M, Ratynskaia S, Tolias P, Cavalier J, Dejarnac R, Gunn J P, Podolnik A 2017 Plasma Phys. Control. Fusion 59 094002

Google Scholar

Google Scholar

[21] Sang C F, Sun J Z, Wang D Z 2011 J. Nucl. Mater. 415 S204

Google Scholar

Google Scholar

[22] Hu W P, Sang C F, Sun Z Y, Wang D Z 2017 Fusion Eng. Des. 116 5

Google Scholar

Google Scholar

[23] 黄艳, 孙继忠, 桑超峰, 丁芳, 王德真 2014 63 035204

Google Scholar

Google Scholar

Huang Y, Sun J Z, Sang C F, Ding F, Wang D Z 2014 Acta Phys. Sin. 63 035204

Google Scholar

Google Scholar

[24] Huang Y, Sun J Z, Hu W P, Sang C F, Wang D Z 2016 Fusion Eng. Des. 102 28

Google Scholar

Google Scholar

[25] Birdsall C K, Langdon A B 1985 Plasma Physics via Computer Simulation (New York: McGraw-Hill) pp1–479

[26] Verboncoeur J P 2005 Plasma Phys. Control. Fusion 47 A231

Google Scholar

Google Scholar

[27] Carslaw H W, Jaeger J C 1959 Conduction of Heat in Solids (Oxford: Clarendon) p2

[28] Behrisch R 2010 J. Surf. Invest-X-Ray 4 549

Google Scholar

Google Scholar

[29] Dittus F W, Boelter L M K 1985 Int. Commun. Heat Mass Transfer 12 3

Google Scholar

Google Scholar

[30] Sieder E N, Tate G E 1936 Ind. Eng. Chem. 28 1429

Google Scholar

Google Scholar

[31] Collier J G, Thome J R 1994 Convective Boiling and Condensation (3rd Ed.) (New York: Clarendon Press) pp109–111

[32] Chen J C 1966 Ind. Eng. Chem. Process Des. Dev. 5 322

Google Scholar

Google Scholar

[33] Robinson K, Hawley J G, Campbell N A F 2003 Proc. Inst. Mech. Eng. D 217 877

Google Scholar

Google Scholar

[34] Kukushkin A S, Pacher H D, Kotov V, Reiter D, Coster D, Pacher G W 2007 Nucl. Fusion 47 698

Google Scholar

Google Scholar

[35] Aymar R, Barabaschi P, Shimomura Y 2002 Plasma Phys. Control. Fusion 44 519

Google Scholar

Google Scholar

[36] Roth J, Tsitrone E, Loarte A, Loarer Th, Counsell G, Neu R, Philipps V, Brezinsek S, Lehnen M, Coad P, Grisolia Ch, Schmid K, Krieger K, Kallenbach A, Lipschultz B, Doerner R, Causey R, Alimov V, Shu W, Ogorodnikova O, Kirschner A, Federici G, Kukushkin A, EFDA PWI Task Force, ITER PWI Team, Fusion for Energy, ITPA SOL/DIV 2009 J. Nucl. Mater. 390–391 1

Google Scholar

Google Scholar

[37] Dejarnac R, Komm M, Gunn J P, Panek R 2009 J. Nucl. Mater. 390–391 818

Google Scholar

Google Scholar

[38] Miloshevsky G V, Hassanein A 2010 Nucl. Fusion 50 115005

Google Scholar

Google Scholar

[39] Loarte A 2003 Plasma Phys. Control. Fusion 45 1549

Google Scholar

Google Scholar

[40] Escourbiac F, Durocher A, Fedosov A, Hirai T, Pitts R A, Gavila P, Riccardi B, Kuznetcov V, Volodin A, Komarov A 2019 Fusion Eng. Des. 146 2036

Google Scholar

Google Scholar

-

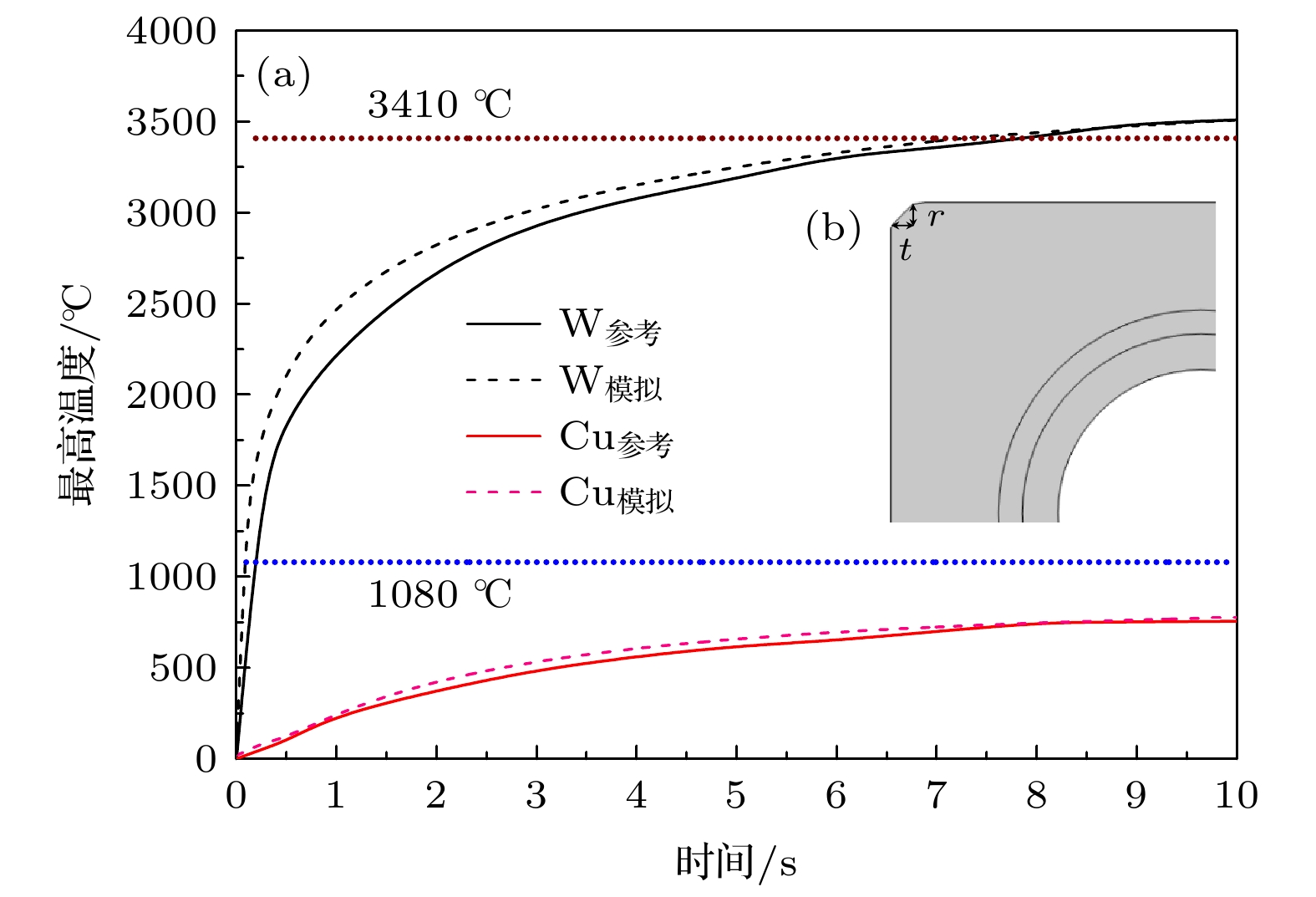

图 2 (a)双倒角瓦片钨材料和铜中间层最高温度模拟结果与现有工作[7]的对比, 排布误差为2.5 mm, 表面热负荷为1.5 MW·m–2; (b)四分之一双倒角瓦片结构图

Fig. 2. (a) Temporal evolution of the highest temperature of W armor and Cu heat sink materials of dual chamfer tile for misalignment of a 2.5 mm and perpendicular heat flux of 1.5 MW·m–2. Here the calculated results are represented by the dash lines, and those represented by the solid lines are taken from the work by Li et al.[7]; (b) schematic diagram of quarter dual chamfer tile.

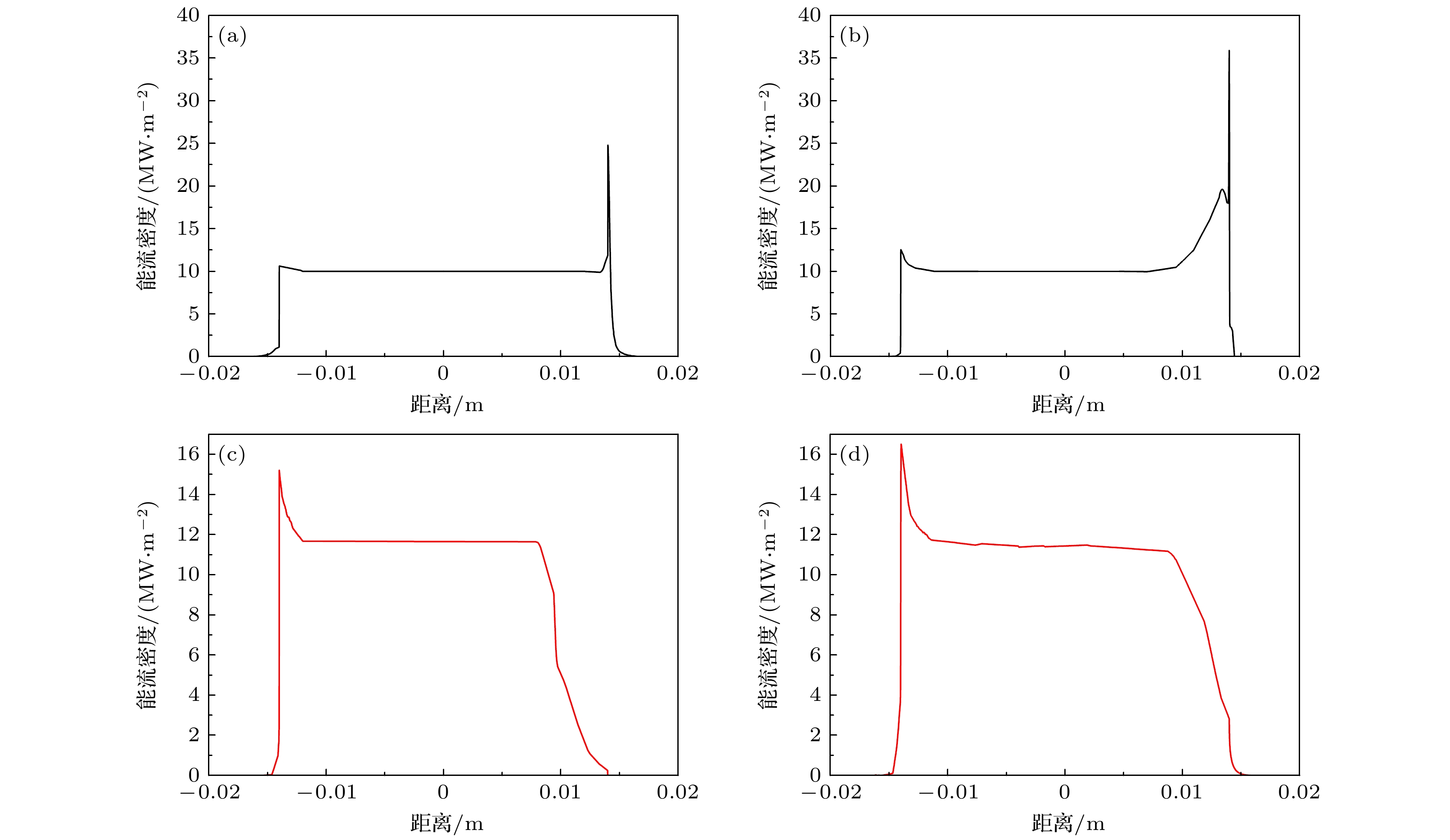

图 3 偏滤器瓦片表面能流密度分布 (a) δ = 0的直角瓦片; (b) δ = 0.3 mm的直角瓦片; (c) δ = 0的斜边瓦片; (d) δ = 0.3 mm的斜边瓦片; 坐标系原点取在瓦片中心, 距离值表示沿着瓦片表面距离瓦片中心的距离, 向右为正, 向左为负

Fig. 3. Energy fluxes received by divertor tile: (a) Unshaped tile for δ = 0; (b) unshaped tile for δ = 0.3 mm; (c) beveled tile for δ = 0; (d) beveled tile for δ = 0.3 mm. Origin of coordinate frame is set at tile center, absolute coordinate value is distance along surface away from center; sign ‘+’ denotes direction to right, and sign ‘–’ to left.

-

[1] Federici G, Skinner C H, Brooks J N, Coad J P, Grisolia C, Haasz A A, Hassanein A, Philipps V, Pitcher C S, Roth J, Wampler W R, Whyte D G 2001 Nucl. Fusion 41 1967

Google Scholar

Google Scholar

[2] Bolt H, Barabash V, Krauss W, Linke J, Neu R, Suzuki S, Yoshida N, ASDEX Upgrade Team 2004 J. Nucl. Mater. 329–333 66

Google Scholar

Google Scholar

[3] Pitts R A, Bonnin X, Escourbiac F, Frerichs H, Gunn J P, Hirai T, Kukushkin A S, Kaveeva E, Miller M A, Moulton D, Rozhansk V Y, Senichenkov I, Sytova E, Schmitz O, Stangeby P C, De Temmerman G, Veselova I, Wiesen S 2019 Nucl. Mater. Energy 20 100696

Google Scholar

Google Scholar

[4] Wang B G, Zhu D Z, Ding R, Chen J L 2017 Plasma Sci. Technol. 19 025603

Google Scholar

Google Scholar

[5] Hirai T, Escourbiac F, Carpentier-Chouchana S, Fedosov A, Ferrand L, Jokinen T, Komarov V, Kukushkin A, Merola M, Mitteau R, Pitts R A, Shu W, Sugihara M, Riccardi B, Suzuki S, Villari R 2013 Fusion Eng. Des. 88 1798

Google Scholar

Google Scholar

[6] Missirlian M, Firdaouss M, Richou M, Languille P, Lecocq S, Lipa M 2013 Fusion Eng. Des. 88 1793

Google Scholar

Google Scholar

[7] Li C J, Zhu D Z, Ding R, Wang B G, Chen J L, Gao B F, Le Y 2020 Nucl. Mater. Energy 25 100847

Google Scholar

Google Scholar

[8] Perkins F W, Post D E, Uckan N A, et al. 1999 Nucl. Fusion 39 2137

Google Scholar

Google Scholar

[9] Loarte A, Saibene G, Sartori R, Riccardo V, Andrew P, Paley J, Fundamenski W, Eich T, Herrmann A, Pautasso G, Kirk A, Counsell G, Federici G, Strohmayer G, Whyte D, Leonard A, Pitts R A, Landman I, Bazylev B, Pestchanyi S 2007 Phys. Scr. T128 222

Google Scholar

Google Scholar

[10] Bazylev B, Janeschitz G, Landman I S, Loarte A, Pestchanyi S E 2007 J. Nucl. Mater. 363–365 1011

Google Scholar

Google Scholar

[11] Bazylev B, Janeschitz G, Landman I S, Pestchanyi S E 2005 Fusion Eng. Des. 75–79 407

Google Scholar

Google Scholar

[12] Coenen J W, Bazylev B, Brezinsek S, Philipps V, Hirai T, Kreter A, Linke J, Sergienko G, Pospieszczyk A, Tanabe T, Ueda Y, Samm U, The TEXTOR-Team 2011 J. Nucl. Mater. 415 S78

Google Scholar

Google Scholar

[13] Chen X H, Ding F, Mao H M, Luo G N, Hu Z H, Xu F, Niu G J 2016 Fusion Eng. Des.108 98

Google Scholar

Google Scholar

[14] El-Din El-Morshedy S 2021 Nucl. Mater. Energy 28 101035

Google Scholar

Google Scholar

[15] Raffray A R, Federici G J 1997 Nucl. Mater. 244 85

Google Scholar

Google Scholar

[16] Federici G, Loarte A, Strohmayer G 2003 Plasma Phys. Control. Fusion 45 1523

Google Scholar

Google Scholar

[17] Dejarnac R, Gunn J P 2007 J. Nucl. Mater. 363–365 560

Google Scholar

Google Scholar

[18] Gunn J P, Carpentier S C, Dejarnac R, Escourbiac F, Hirai T, Komm M, Kukushkin A, Panayotis S, Pitts R A 2016 Nucl. Mater. Energ. 12 75

Google Scholar

Google Scholar

[19] Gunn J P, Carpentier-Chouchana S, Escourbiac F, Hirai T, Panayotis S, Pitts R A, Corre Y, Dejarnac R, Firdaouss M, Kočan M, Komm M, Kukushkin A, Languille P, Missirlian M, Zhao W, Zhong G 2017 Nucl. Fusion 57 046025

Google Scholar

Google Scholar

[20] Komm M, Ratynskaia S, Tolias P, Cavalier J, Dejarnac R, Gunn J P, Podolnik A 2017 Plasma Phys. Control. Fusion 59 094002

Google Scholar

Google Scholar

[21] Sang C F, Sun J Z, Wang D Z 2011 J. Nucl. Mater. 415 S204

Google Scholar

Google Scholar

[22] Hu W P, Sang C F, Sun Z Y, Wang D Z 2017 Fusion Eng. Des. 116 5

Google Scholar

Google Scholar

[23] 黄艳, 孙继忠, 桑超峰, 丁芳, 王德真 2014 63 035204

Google Scholar

Google Scholar

Huang Y, Sun J Z, Sang C F, Ding F, Wang D Z 2014 Acta Phys. Sin. 63 035204

Google Scholar

Google Scholar

[24] Huang Y, Sun J Z, Hu W P, Sang C F, Wang D Z 2016 Fusion Eng. Des. 102 28

Google Scholar

Google Scholar

[25] Birdsall C K, Langdon A B 1985 Plasma Physics via Computer Simulation (New York: McGraw-Hill) pp1–479

[26] Verboncoeur J P 2005 Plasma Phys. Control. Fusion 47 A231

Google Scholar

Google Scholar

[27] Carslaw H W, Jaeger J C 1959 Conduction of Heat in Solids (Oxford: Clarendon) p2

[28] Behrisch R 2010 J. Surf. Invest-X-Ray 4 549

Google Scholar

Google Scholar

[29] Dittus F W, Boelter L M K 1985 Int. Commun. Heat Mass Transfer 12 3

Google Scholar

Google Scholar

[30] Sieder E N, Tate G E 1936 Ind. Eng. Chem. 28 1429

Google Scholar

Google Scholar

[31] Collier J G, Thome J R 1994 Convective Boiling and Condensation (3rd Ed.) (New York: Clarendon Press) pp109–111

[32] Chen J C 1966 Ind. Eng. Chem. Process Des. Dev. 5 322

Google Scholar

Google Scholar

[33] Robinson K, Hawley J G, Campbell N A F 2003 Proc. Inst. Mech. Eng. D 217 877

Google Scholar

Google Scholar

[34] Kukushkin A S, Pacher H D, Kotov V, Reiter D, Coster D, Pacher G W 2007 Nucl. Fusion 47 698

Google Scholar

Google Scholar

[35] Aymar R, Barabaschi P, Shimomura Y 2002 Plasma Phys. Control. Fusion 44 519

Google Scholar

Google Scholar

[36] Roth J, Tsitrone E, Loarte A, Loarer Th, Counsell G, Neu R, Philipps V, Brezinsek S, Lehnen M, Coad P, Grisolia Ch, Schmid K, Krieger K, Kallenbach A, Lipschultz B, Doerner R, Causey R, Alimov V, Shu W, Ogorodnikova O, Kirschner A, Federici G, Kukushkin A, EFDA PWI Task Force, ITER PWI Team, Fusion for Energy, ITPA SOL/DIV 2009 J. Nucl. Mater. 390–391 1

Google Scholar

Google Scholar

[37] Dejarnac R, Komm M, Gunn J P, Panek R 2009 J. Nucl. Mater. 390–391 818

Google Scholar

Google Scholar

[38] Miloshevsky G V, Hassanein A 2010 Nucl. Fusion 50 115005

Google Scholar

Google Scholar

[39] Loarte A 2003 Plasma Phys. Control. Fusion 45 1549

Google Scholar

Google Scholar

[40] Escourbiac F, Durocher A, Fedosov A, Hirai T, Pitts R A, Gavila P, Riccardi B, Kuznetcov V, Volodin A, Komarov A 2019 Fusion Eng. Des. 146 2036

Google Scholar

Google Scholar

计量

- 文章访问数: 3750

- PDF下载量: 67

- 被引次数: 0

下载:

下载: