-

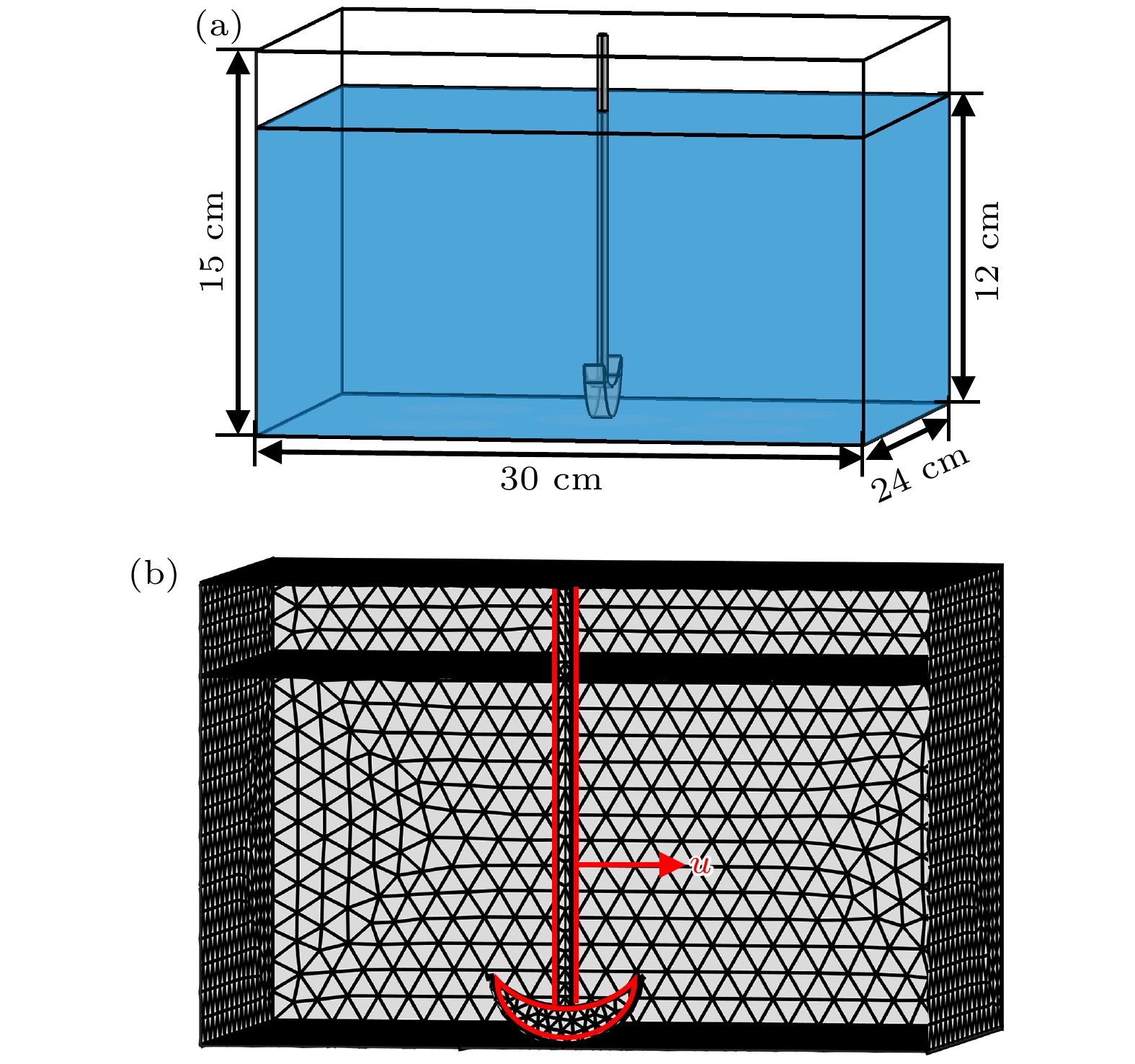

涡流场影响着声场分布, 进而影响着声空化特性, 以机械搅拌产生的涡流场为研究对象, 使用COMSOL软件数值模拟了不同搅拌速度下的声场分布情况. 结果显示, 机械搅拌增加了声场分布的均匀性和声压幅值. 接下来将仿真得到的瞬时声压值用Origin软件拟合, 然后将拟合得到的声压函数代入Keller-Miksis气泡动力学方程中, 得到了不同搅拌速度下空化泡的半径随时间的变化情况, 从计算结果中发现, 未加机械搅拌的条件下, 只有z = 7.3 cm截面上有空化效应产生. 最后根据所得到的空化泡半径, 计算了空化泡内部的温度. 结果显示, 空化泡在有搅拌存在的条件下, 内部温度得到了大幅增加, 当搅拌速度达到1000 r/min后, 空化泡内部温度会随着搅拌速度的增加而降低. 最后设计实验验证了仿真结果. 仿真得到的结果不仅从理论上解释了机械搅拌提高有机溶液超声降解率的原因, 还发现了过高的搅拌速度会降低声空化强度, 从而降低声化学反应速率, 这为通过机械搅拌来进一步提高超声降解率提供了新思路.In order to further investigate the effect of the vortex induced by mechanical agitation on the ultrasonic degradation rate of organic solution, with water used as a medium, the acoustic field distributions at different stirring speeds are simulated by using the simulation software COMSOL. The simulation of acoustic field distribution is divided into two steps. First, the flow field distribution in the cleaning tank is obtained by using the Navier-Stokes equation and the continuity equation under the corresponding boundary conditions. Next, the velocity and pressure in the flow field are substituted into the acoustic wave equation to obtain the acoustic field distribution. In addition, the instantaneous acoustic pressure obtained by simulation is fitted by Origin, and the fitting curve shows a good sinusoidal shape. Then, substituting the fitting function into the Keller-Miksis equation, the variations of radius of the cavitation bubble with time at different stirring speeds are obtained. Finally, the temperature of the cavitation bubble is calculated from the obtained radius. The results show that mechanical agitation increases the uniformity of acoustic field distribution and the amplitude of acoustic pressure, and that the bubble temperature is greatly enhanced due to the agitation. At the same time, it is also found that the internal temperature of the bubble first increases with the stirring speed increasing. When the stirring speed reaches 1500 r/min, the temperature begins to decrease with the stirring speed increasing. The temperature inside the cavitation bubble reflects the intensity of acoustic cavitation. The higher the temperature, the greater the intensity of acoustic cavitation will be. Therefore, it can be concluded that the acoustic cavitation intensity will decrease when the stirring speed is too high. Therefore, though mechanical agitation can improve the acoustic cavitation intensity, too high stirring speed can reduce the acoustic cavitation intensity. In order to verify the simulation results, the degradation of methylene blue is performed by ultrasound coupled with mechanical agitation, and the experimental results show that the degradation rate of the solution without mechanical stirring is lowest. The degradation rate of the solution increases with the stirring speed increasing. When the stirring speed reaches 1000 r/min, the degradation rate of the solution is the same as that at 600 r/min, and then decreases with the stirring speed increasing. It can be found that the experimental results are consistent with the simulation results. The simulation results not only theoretically explain why mechanical agitation can improve the ultrasonic degradation rate of organic solution, but also indicate that too high stirring speed can reduce the acoustic cavitation intensity, thus reducing the sonochemical reaction rate. Therefore, the results obtained in this work provide a new idea for further improving the ultrasonic degradation rate by mechanical agitation.

-

Keywords:

- vortex /

- ultrasonic degradation rate /

- acoustic field /

- temperature

[1] Mahamuni N N, Adewuyi A G 2010 Ultrason. Sonochem. 17 990

Google Scholar

Google Scholar

[2] 李宁, 闫家望 2021 中国资源综合利用 39 99

Google Scholar

Google Scholar

Li N, Yan J W 2021 China Resources Comprehensive Utilization 39 99

Google Scholar

Google Scholar

[3] Shimizu N, Ogino C, Dadjour M F, Murata T 2007 Ultrason. Sonochem. 14 184

Google Scholar

Google Scholar

[4] Suslick K S, Didenko Y, Fang M M, et al. 1999 Phil. Trans. R. Soc. A 357 335

Google Scholar

Google Scholar

[5] Suslick K S, Price G J 1999 Annu. Rev. Mater. Sci 29 295

Google Scholar

Google Scholar

[6] Kobayashi D, Honma C, Suzuki A, Takahashi T, Matsumoto H, Kuroda C, Otake K, Shono A 2012 Ultrason. Sonochem. 19 745

Google Scholar

Google Scholar

[7] Nikpassand M, Fekri L Z, Farokhian P 2016 Ultrason. Sonochem. 28 341

Google Scholar

Google Scholar

[8] Shanei A, Shanei M M 2017 Ultrason. Sonochem. 34 45

Google Scholar

Google Scholar

[9] Zhai W, Liu H M, Hong Z Y, Xie W J, Wei B 2017 Ultrason. Sonochem. 34 130

Google Scholar

Google Scholar

[10] Jawale R H, Gogate P R 2018 Ultrason. Sonochem. 40 89

Google Scholar

Google Scholar

[11] Kobayashi D, Honma C, Matsumoto H, Otake K, Shono A 2018 Open J. Acoust. 8 61

Google Scholar

Google Scholar

[12] Kwedi-Nsah L M, Kobayashi T 2019 Ultrason. Sonochem. 52 69

Google Scholar

Google Scholar

[13] Wang J, Wang Z, Wolfson J M, Pingtian G, Huang S D 2019 Ultrason. Sonochem. 55 273

Google Scholar

Google Scholar

[14] Serna-Galvis E A, Montoya-Rodríguez D, Isaza-Pineda L, Ibáñez M, Hernández F, Moncayo-Lasso A, Torres-Palma R A 2019 Ultrason. Sonochem. 50 157

Google Scholar

Google Scholar

[15] Fang Y, Hariu D, Yamamoto T, Komarov S 2019 Ultrason. Sonochem. 52 318

Google Scholar

Google Scholar

[16] Shen Z Z 2020 Chin. Phys. B 29 014304

Google Scholar

Google Scholar

[17] Lesko T, Colussi A G, Hoffmann M R 2006 Environ. Sci. Technol. 40 6818

Google Scholar

Google Scholar

[18] Yasuda K, Matsuura K, Asakura1 Y, Koda S 2009 Jpn. J. Appl. Phys. 48 07GH04

Google Scholar

Google Scholar

[19] Hatanaka S, Yasui K, Kozuka T, Tuziuti T, Mitome H 2006 Ultrasonics 44 e435

Google Scholar

Google Scholar

[20] Kojima Y, Asakura Y, Sugiyama G, Koda S 2010 Ultrason. Sonochem. 17 978

Google Scholar

Google Scholar

[21] Wood R J, Vévert C, Lee J, Bussemaker M J 2020 Ultrason. Sonochem. 63 104892

Google Scholar

Google Scholar

[22] Nakui H, Okitsu K, Maeda Y, Nishimura R. 2007 J. Hazard. Mater. 146 636

Google Scholar

Google Scholar

[23] Zhang X G, Hao C C, Ma C, Shen Z Z 2019 Ultrason. Sonochem. 58 104691

Google Scholar

Google Scholar

[24] Yang Y, Yang J k, Zuo J L, Li Y, He S, Yang X, Zhang K 2011 Water Res. 45 3439

Google Scholar

Google Scholar

[25] Pierce A D 1990 J. Acoust. Soc. Am. 87 2292

Google Scholar

Google Scholar

[26] 沈壮志, 林书玉 2011 60 104302

Google Scholar

Google Scholar

Shen Z Z, Lin S Y 2011 Acta Phys. Sin. 60 104302

Google Scholar

Google Scholar

[27] Saez V, Frias-Fsrrer A, Iniesta J, Gonzalez J, Aldaz A, Riera E 2005 Ultrason. Sonochem. 12 59

Google Scholar

Google Scholar

[28] Yasui K, Kozuka T, Tuziuti T, Towata A, Iida Y, King J, Macey P 2007 Ultrason. Sonochem. 14 605

Google Scholar

Google Scholar

[29] Zhang Z B, Gao T T, Liu X Y, Li D W, Zhao J W, Lei Y Q, Wang Y K 2018 Ultrason. Sonochem. 42 787

Google Scholar

Google Scholar

[30] Vanhille C 2016 Ultrason. Sonochem. 31 631

Google Scholar

Google Scholar

[31] 陈伟中 2014 声空化物理 (北京: 科学出版社)第160页

Chen W Z 2014 Acoustic Cavitation Physics (Beijing: Science Press) p160 (in Chinese)

[32] Liu L Y, Wen J J, Yang Y, Tian W 2013 Ultrason. Sonochem 20 696

Google Scholar

Google Scholar

[33] 杜功焕, 朱哲民, 龚秀芬 2012 声学基础 (南京: 南京大学出版社) 第137页

Du G H, Zhu Z M, Gong X F 2012 Fundamentals of Acoustics (Nanjing: Nanjing University Press) p137 (in Chinese)

[34] Berthet R, Astruc D Astruc D 2003 J. Comput. Phys. 190 64

Google Scholar

Google Scholar

[35] Li Z W, Xu Z W, Zhao D G, Chen S, Yan J C 2021 Ultrason. Sonochem. 71 105356

Google Scholar

Google Scholar

-

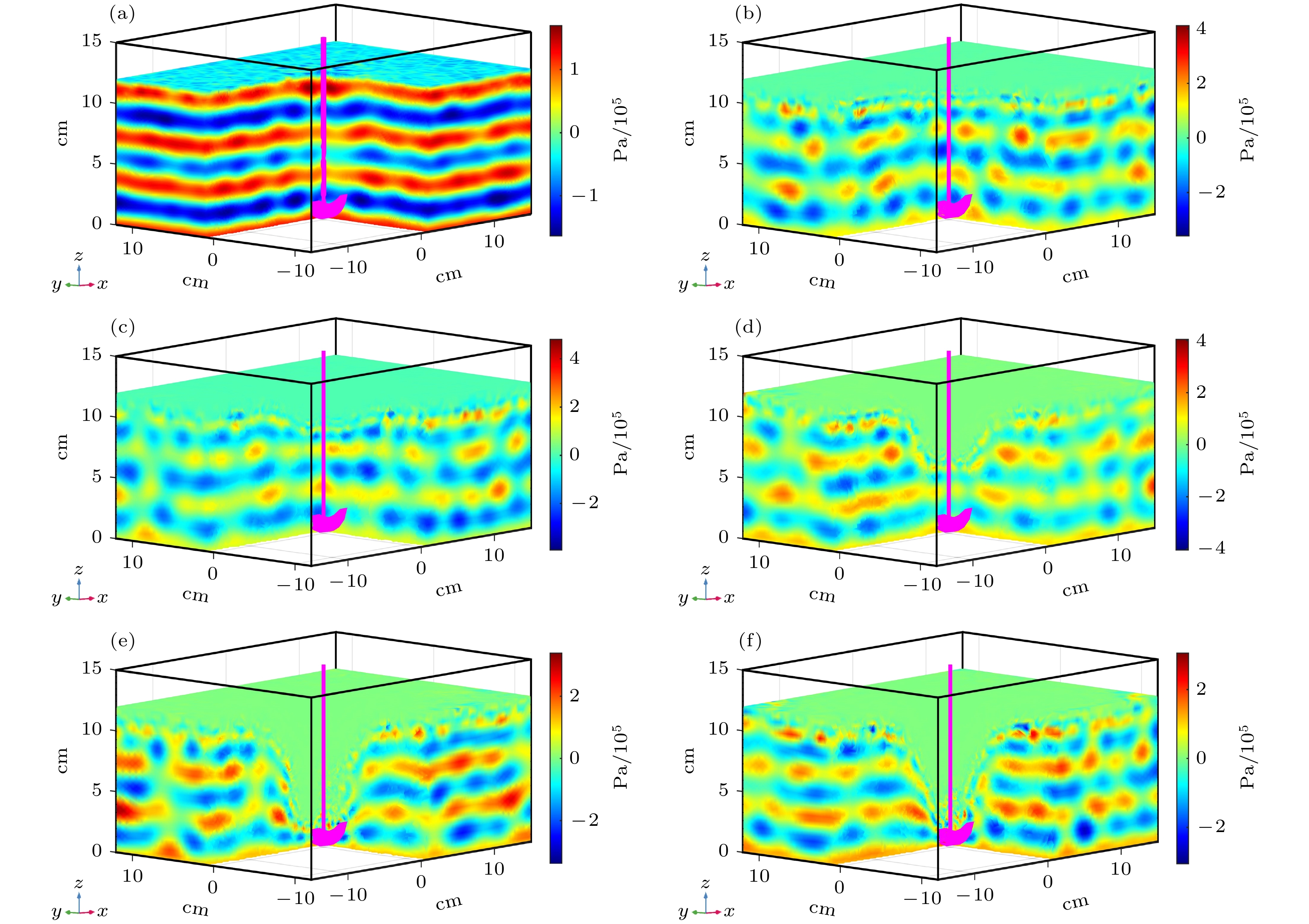

图 5 不同搅拌速度下, 提取点处的声压随时间变化图 (a) 0 r/min; (b) 300 r/min; (c) 600 r/min; (d) 1000 r/min; (e) 1500 r/min; (f) 2000 r/min

Fig. 5. Acoustic pressure versus time for extracted point at the stirring speed of various value: (a) 0 r/min; (b) 300 r/min; (c) 600 r/min; (d) 1000 r/min; (e) 1500 r/min; (f) 2000 r/min.

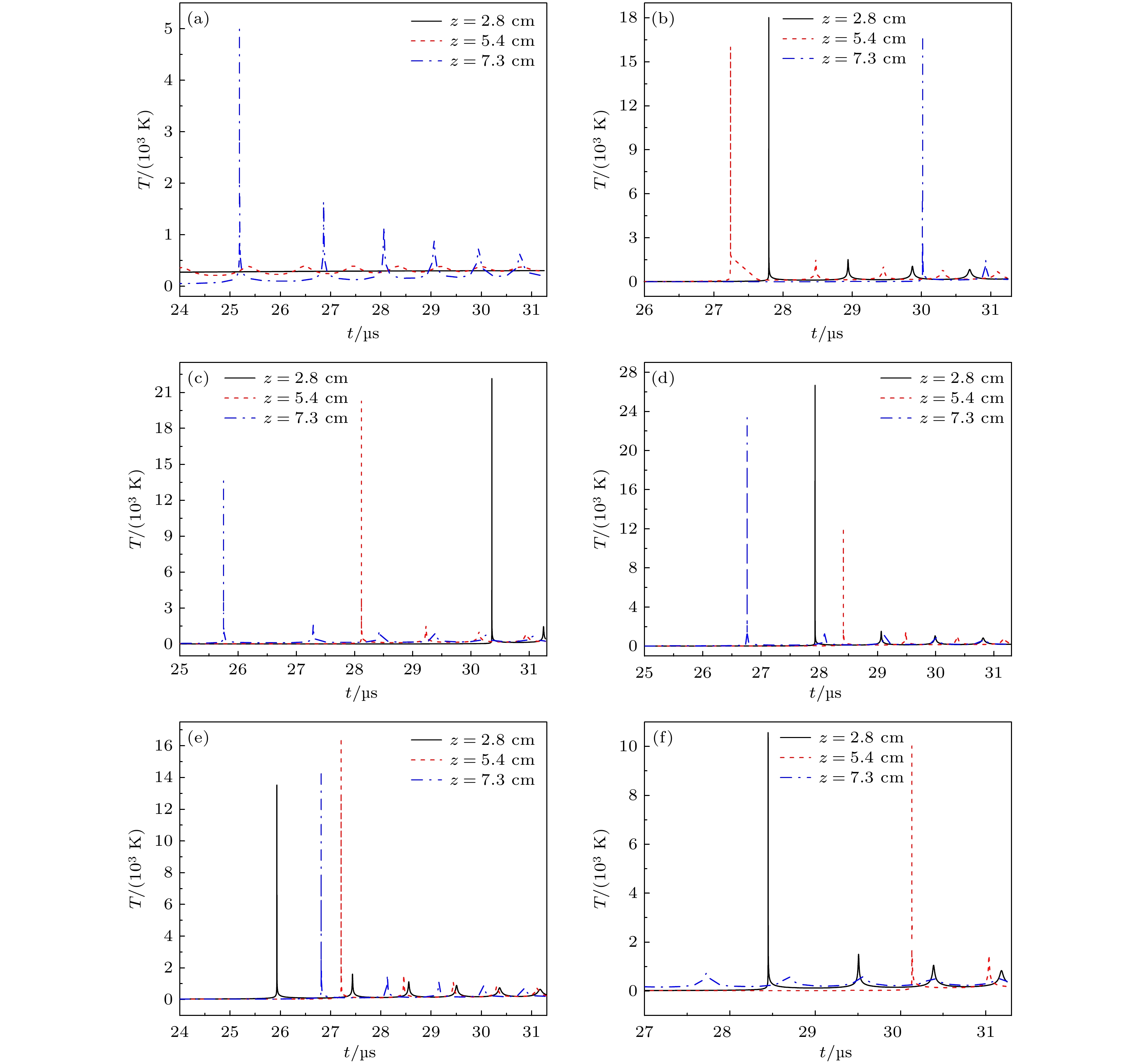

图 7 不同搅拌速度下, 空化泡内部的温度随时间变化图 (a) 0 r/min; (b) 300 r/min; (c) 600 r/min; (d) 1000 r/min; (e) 1500 r/min; (f) 2000 r/min

Fig. 7. Internal temperature of bubble under distinct stirring speeds in the plane of various value: (a) 0 r/min; (b) 300 r/min; (c) 600 r/min; (d) 1000 r/min; (e) 1500 r/min; (f) 2000 r/min.

表 1 材料参数.

Table 1. Material parameters.

材料 $ {\rho _0} $/($ {\rm{kg}} \cdot {{\rm{m}}^{{\rm{ - 3}}}} $) $ {c_0} $/(m s–1) $ \mu $/(Pa s) 水 1000 1500 1.01 × 10–3 空气 1.29 340 1.79 × 10–5 -

[1] Mahamuni N N, Adewuyi A G 2010 Ultrason. Sonochem. 17 990

Google Scholar

Google Scholar

[2] 李宁, 闫家望 2021 中国资源综合利用 39 99

Google Scholar

Google Scholar

Li N, Yan J W 2021 China Resources Comprehensive Utilization 39 99

Google Scholar

Google Scholar

[3] Shimizu N, Ogino C, Dadjour M F, Murata T 2007 Ultrason. Sonochem. 14 184

Google Scholar

Google Scholar

[4] Suslick K S, Didenko Y, Fang M M, et al. 1999 Phil. Trans. R. Soc. A 357 335

Google Scholar

Google Scholar

[5] Suslick K S, Price G J 1999 Annu. Rev. Mater. Sci 29 295

Google Scholar

Google Scholar

[6] Kobayashi D, Honma C, Suzuki A, Takahashi T, Matsumoto H, Kuroda C, Otake K, Shono A 2012 Ultrason. Sonochem. 19 745

Google Scholar

Google Scholar

[7] Nikpassand M, Fekri L Z, Farokhian P 2016 Ultrason. Sonochem. 28 341

Google Scholar

Google Scholar

[8] Shanei A, Shanei M M 2017 Ultrason. Sonochem. 34 45

Google Scholar

Google Scholar

[9] Zhai W, Liu H M, Hong Z Y, Xie W J, Wei B 2017 Ultrason. Sonochem. 34 130

Google Scholar

Google Scholar

[10] Jawale R H, Gogate P R 2018 Ultrason. Sonochem. 40 89

Google Scholar

Google Scholar

[11] Kobayashi D, Honma C, Matsumoto H, Otake K, Shono A 2018 Open J. Acoust. 8 61

Google Scholar

Google Scholar

[12] Kwedi-Nsah L M, Kobayashi T 2019 Ultrason. Sonochem. 52 69

Google Scholar

Google Scholar

[13] Wang J, Wang Z, Wolfson J M, Pingtian G, Huang S D 2019 Ultrason. Sonochem. 55 273

Google Scholar

Google Scholar

[14] Serna-Galvis E A, Montoya-Rodríguez D, Isaza-Pineda L, Ibáñez M, Hernández F, Moncayo-Lasso A, Torres-Palma R A 2019 Ultrason. Sonochem. 50 157

Google Scholar

Google Scholar

[15] Fang Y, Hariu D, Yamamoto T, Komarov S 2019 Ultrason. Sonochem. 52 318

Google Scholar

Google Scholar

[16] Shen Z Z 2020 Chin. Phys. B 29 014304

Google Scholar

Google Scholar

[17] Lesko T, Colussi A G, Hoffmann M R 2006 Environ. Sci. Technol. 40 6818

Google Scholar

Google Scholar

[18] Yasuda K, Matsuura K, Asakura1 Y, Koda S 2009 Jpn. J. Appl. Phys. 48 07GH04

Google Scholar

Google Scholar

[19] Hatanaka S, Yasui K, Kozuka T, Tuziuti T, Mitome H 2006 Ultrasonics 44 e435

Google Scholar

Google Scholar

[20] Kojima Y, Asakura Y, Sugiyama G, Koda S 2010 Ultrason. Sonochem. 17 978

Google Scholar

Google Scholar

[21] Wood R J, Vévert C, Lee J, Bussemaker M J 2020 Ultrason. Sonochem. 63 104892

Google Scholar

Google Scholar

[22] Nakui H, Okitsu K, Maeda Y, Nishimura R. 2007 J. Hazard. Mater. 146 636

Google Scholar

Google Scholar

[23] Zhang X G, Hao C C, Ma C, Shen Z Z 2019 Ultrason. Sonochem. 58 104691

Google Scholar

Google Scholar

[24] Yang Y, Yang J k, Zuo J L, Li Y, He S, Yang X, Zhang K 2011 Water Res. 45 3439

Google Scholar

Google Scholar

[25] Pierce A D 1990 J. Acoust. Soc. Am. 87 2292

Google Scholar

Google Scholar

[26] 沈壮志, 林书玉 2011 60 104302

Google Scholar

Google Scholar

Shen Z Z, Lin S Y 2011 Acta Phys. Sin. 60 104302

Google Scholar

Google Scholar

[27] Saez V, Frias-Fsrrer A, Iniesta J, Gonzalez J, Aldaz A, Riera E 2005 Ultrason. Sonochem. 12 59

Google Scholar

Google Scholar

[28] Yasui K, Kozuka T, Tuziuti T, Towata A, Iida Y, King J, Macey P 2007 Ultrason. Sonochem. 14 605

Google Scholar

Google Scholar

[29] Zhang Z B, Gao T T, Liu X Y, Li D W, Zhao J W, Lei Y Q, Wang Y K 2018 Ultrason. Sonochem. 42 787

Google Scholar

Google Scholar

[30] Vanhille C 2016 Ultrason. Sonochem. 31 631

Google Scholar

Google Scholar

[31] 陈伟中 2014 声空化物理 (北京: 科学出版社)第160页

Chen W Z 2014 Acoustic Cavitation Physics (Beijing: Science Press) p160 (in Chinese)

[32] Liu L Y, Wen J J, Yang Y, Tian W 2013 Ultrason. Sonochem 20 696

Google Scholar

Google Scholar

[33] 杜功焕, 朱哲民, 龚秀芬 2012 声学基础 (南京: 南京大学出版社) 第137页

Du G H, Zhu Z M, Gong X F 2012 Fundamentals of Acoustics (Nanjing: Nanjing University Press) p137 (in Chinese)

[34] Berthet R, Astruc D Astruc D 2003 J. Comput. Phys. 190 64

Google Scholar

Google Scholar

[35] Li Z W, Xu Z W, Zhao D G, Chen S, Yan J C 2021 Ultrason. Sonochem. 71 105356

Google Scholar

Google Scholar

计量

- 文章访问数: 8026

- PDF下载量: 122

- 被引次数: 0

下载:

下载: