-

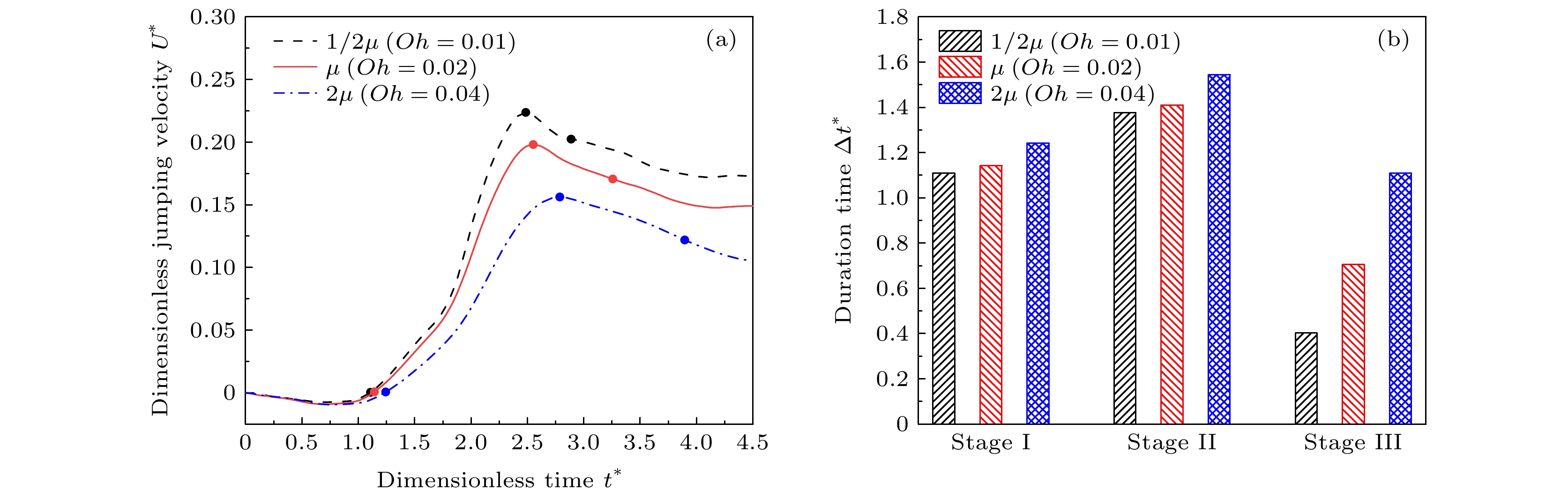

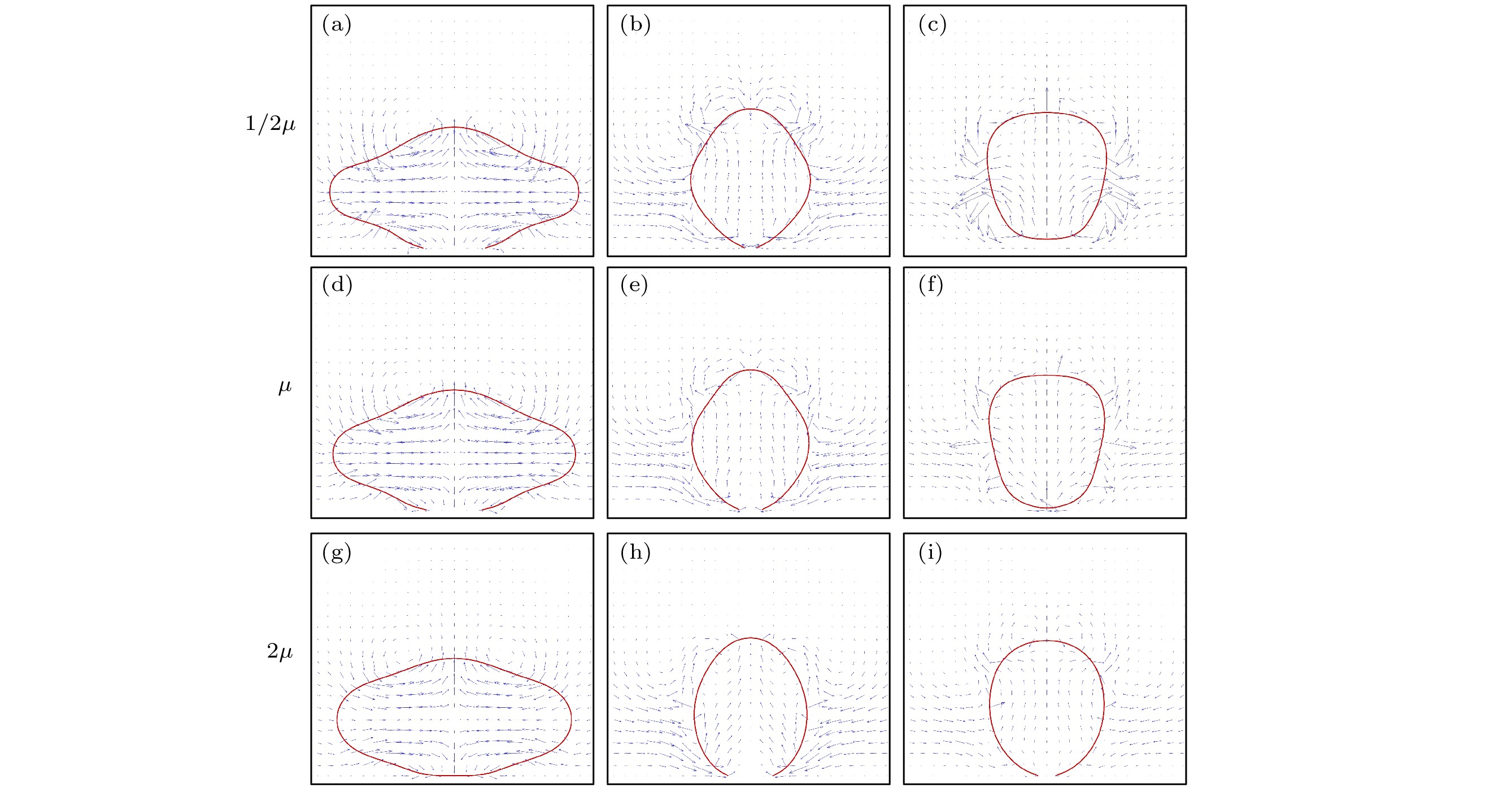

超疏水表面上液滴因聚并诱导而引起的自弹跳行为具有巨大的潜在应用价值, 因此有关问题引起了广泛关注. 目前液滴的物性参数对其自弹跳特性的影响却鲜有报道. 本文数值模拟了不同的液体物性参数下液滴的聚并自弹跳行为, 并利用灰色关联法研究了物性参数变化分别与液滴跳起时的真实弹跳速度及液滴和表面的真实接触时间的关联程度. 在无量纲的时间条件下, 液滴的聚并自弹跳的动力学特性仅受Oh数的影响. 在真实的时间条件下, 黏度变化与液滴聚并所需的真实时间无关, 而减小密度比会同时减少聚并过程和跳起过程中所需的真实时间. 无量纲的弹跳速度随着Oh数的增大而减小, 而减小黏度和密度都会增加液滴跳起时的真实弹跳速度. 根据灰色关联度的计算结果可知, 黏度的变化与真实弹跳速度的关联性更高, 密度的变化与真实接触时间关联性更高.Coalescence-induced self-propelled jumping of droplets on superhydrophobic surfaces has been widely concerned because of a great number of potential applications such as in the enhancement of condensation heat transfer, self-cleaning and anti-icing. The droplet jumping phenomenon exists in a gas-liquid two-phase system, and the physical parameters of fluid cannot be ignored. However, there are few reports on the influence of physical parameters on droplet jumping dynamics at present. In this paper, the three-dimensional volume-of-fluid method is used to simulate the coalescence-induced self-propelled jumping behaviors of droplets, then the energy terms are studied, and finally the grey relational analysis method is used to calculate the relation degree of the change of physical parameters (the viscosity and the density) to the real jumping velocity and the real solid-liquid contact time at the droplet departure time, respectively. Based on the changing trend of jumping velocity, the process of coalescence-induced self-propelled jumping can be divided into four stages, namely, the expansion of liquid bridge, the impact between the liquid bridge and the surface, the droplet departure from the surface, and the deceleration and oscillation in the air. Under the condition of dimensionless time, the dynamic characteristics of coalescence and jumping of droplets are affected only by Oh number, which is independent of the viscosity and the density. In addition, the change of Oh number only affects the above third stage of droplet departure from the surface. Under the condition of real time, the varied viscosity has no connection with the real time of droplet coalescence, and it only changes the real time of the third stage before droplet jumping. Meanwhile, the dimensionless jumping velocity decreases with Oh number increasing, while the real jumping velocity increases when the viscosity and the density both descend. According to the calculated results of grey relational degree, the relation between the change of viscosity and the real jumping velocity is greater, while the relation between the change of density and the real contact time is greater. This work not only is favorable for a better understanding of droplet jumping, but also provides more ideas and theoretical bases for follow-up relevant studies.

-

Keywords:

- physical parameters /

- droplet jumping /

- grey relational analysis /

- superhydrophobic surface

[1] Boreyko J B, Chen C H 2009 Phys. Rev. Lett. 103 184501

Google Scholar

Google Scholar

[2] Chen X, Wu J, Ma R, Hua M, Koratkar N, Yao S, Wang Z 2011 Adv. Funct. Mater. 21 4617

Google Scholar

Google Scholar

[3] Miljkovic N, Enright R, Nam Y, Lopez K, Dou N, Sack J, Wang E N 2013 Nano Lett. 13 179

Google Scholar

Google Scholar

[4] He M, Ding Y, Chen J, Song Y 2016 ACS Nano 10 9456

Google Scholar

Google Scholar

[5] Han T, Kwak H J, Kim J H, Kwon J T, Kim M H 2019 Langmuir 35 9093

Google Scholar

Google Scholar

[6] Hou Y, Yu M, Chen X, Wang Z, Yao S 2015 ACS Nano 9 71

Google Scholar

Google Scholar

[7] Zhu J, Luo Y, Tian J, Li J, Gao X 2015 ACS Appl. Mater. Interfaces 7 10660

Google Scholar

Google Scholar

[8] Zhao Y, Luo Y, Zhu J, Li J, Gao X 2015 ACS Appl. Mater. Interfaces 7 11719

Google Scholar

Google Scholar

[9] Watson G S, Gellender M, Watson J A 2014 Biofouling 30 427

Google Scholar

Google Scholar

[10] Wisdom K M, Watson J A, Qu X, Liu F, Watson G S, Chen C H 2013 Proc. Natl. Acad. Sci. U. S. A. 110 7992

Google Scholar

Google Scholar

[11] Chavez R L, Liu F, Feng J J, Chen C H 2016 Appl. Phys. Lett. 109 011601

Google Scholar

Google Scholar

[12] Boreyko J B, Collier C P 2013 ACS Nano 7 1618

Google Scholar

Google Scholar

[13] Wiedenheft K F, Guo H A, Qu X, Boreyko J B, Liu F, Zhang K, Eid F, Choudhury A, Li Z, Chen C H 2017 Appl. Phys. Lett. 110 141601

Google Scholar

Google Scholar

[14] Liu F, Ghigliotti G, Feng J J, Chen C H 2014 J. Fluid Mech. 752 39

Google Scholar

Google Scholar

[15] Liu F, Ghigliotti G, Feng J J, Chen C H 2014 J. Fluid Mech. 752 22

Google Scholar

Google Scholar

[16] Farokhirad S, Morris J F, Lee T 2015 Phys. Fluids 27 102102

Google Scholar

Google Scholar

[17] Farokhirad S, Lee T 2017 Int. J. Multiphase Flow 95 220

Google Scholar

Google Scholar

[18] Shi Y, Tang G H, Xia H H 2015 Int. J. Heat Mass Transfer 88 445

Google Scholar

Google Scholar

[19] Wang K, Li R, Liang Q, Jiang R, Zheng Y, Lan Z, Ma X 2017 Appl. Phys. Lett. 111 061603

Google Scholar

Google Scholar

[20] Wang Y, Ming P 2018 AIP Adv. 8 065320

Google Scholar

Google Scholar

[21] Wang Y, Ming P 2019 Phys. Fluids 31 122108

Google Scholar

Google Scholar

[22] Wasserfall J, Figueiredo P, Kneer R, Rohlfs W, Pischke P 2017 Phys. Rev. Fluids 2 123601

Google Scholar

Google Scholar

[23] Khatir Z, Kubiak K Z, Jimack P K, Mathia T G 2016 Appl. Therm. Eng. 106 1337

Google Scholar

Google Scholar

[24] Chu F, Yuan Z, Zhang X, Wu X 2018 Int. J. Heat Mass Transfer 121 315

Google Scholar

Google Scholar

[25] Attarzadeh R, Dolatabadi A 2017 Phys. Fluids 29 012104

Google Scholar

Google Scholar

[26] Liang Z, Keblinski P 2015 Appl. Phys. Lett. 107 143105

Google Scholar

Google Scholar

[27] Gao S, Liao Q, Liu W, Liu Z 2018 J. Phys. Chem. Lett. 9 13

Google Scholar

Google Scholar

[28] Wang Y, Ming P 2021 J. Appl. Phys. 129 014702

Google Scholar

Google Scholar

[29] 刘天庆, 孙玮, 李香琴, 孙相彧, 艾宏儒 2014 63 086801

Google Scholar

Google Scholar

Liu T Q, Sun W, Li X Q, Sun X Y, Ai H R 2014 Acta Phys. Sin. 63 086801

Google Scholar

Google Scholar

[30] Mouterde T, Nguyen T V, Takahashi H, Clanet C, Shimoyama I, Quéré D 2017 Phys. Rev. Fluids 2 112001

Google Scholar

Google Scholar

[31] 王晨阳, 段倩倩, 周凯, 姚静, 苏敏, 傅意超, 纪俊羊, 洪鑫, 刘雪芹, 汪志勇 2020 69 100701

Google Scholar

Google Scholar

Wang C Y, Duan Q Q, Zhou K, Yao J, Su M, Fu Y C, Ji J Y, Hong X, Liu X Q, Wang Z Y 2020 Acta Phys. Sin. 69 100701

Google Scholar

Google Scholar

-

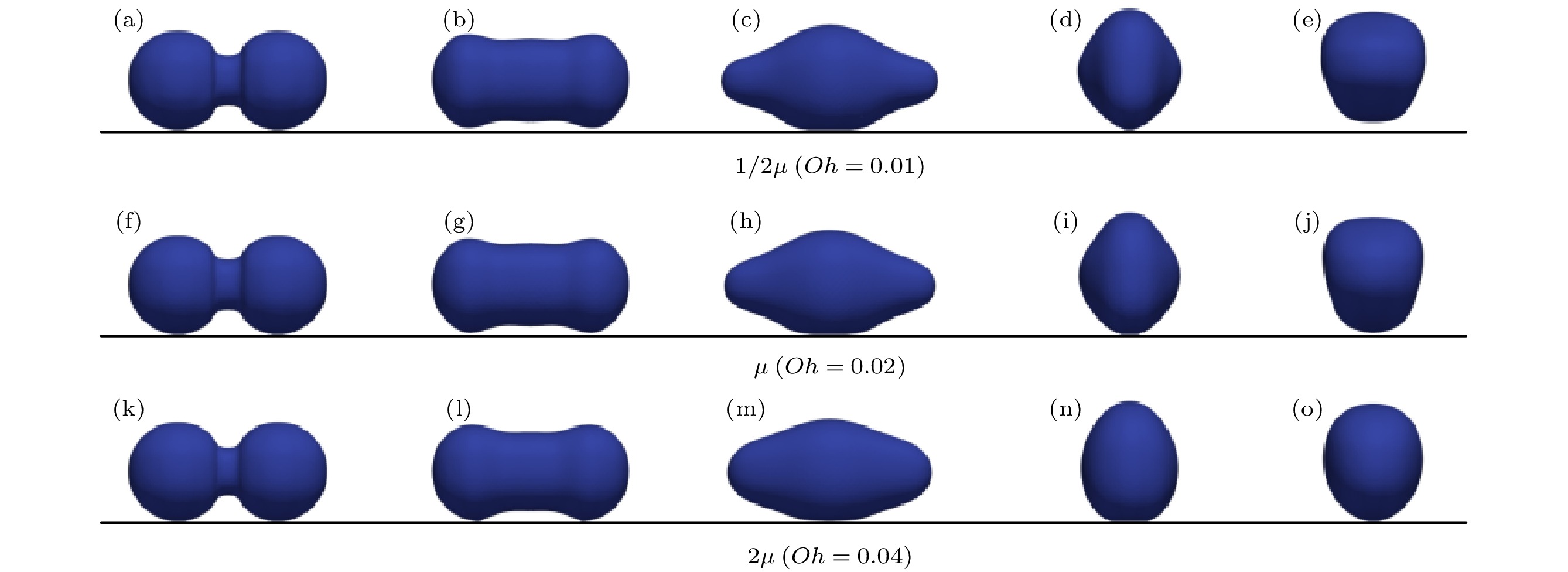

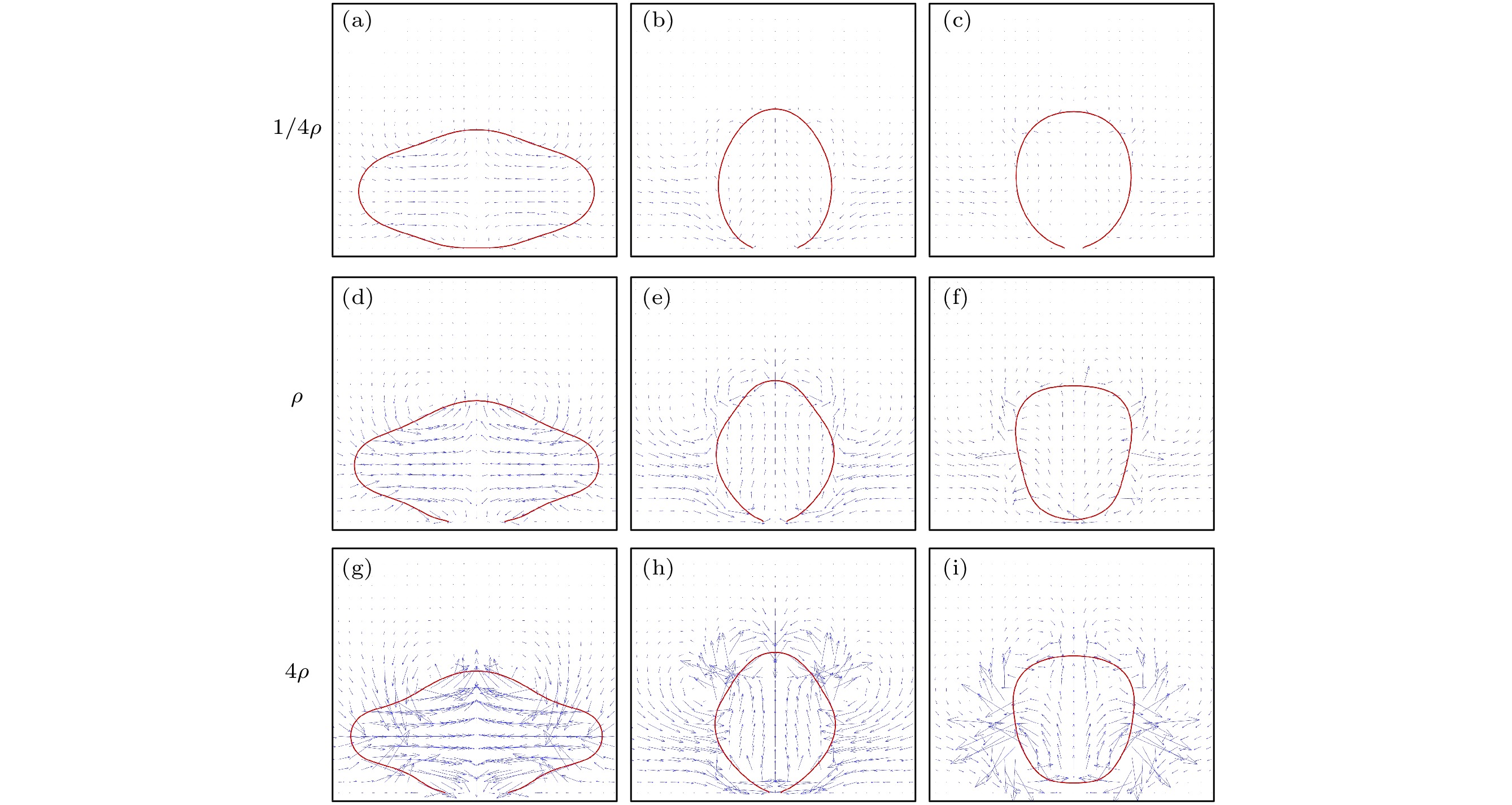

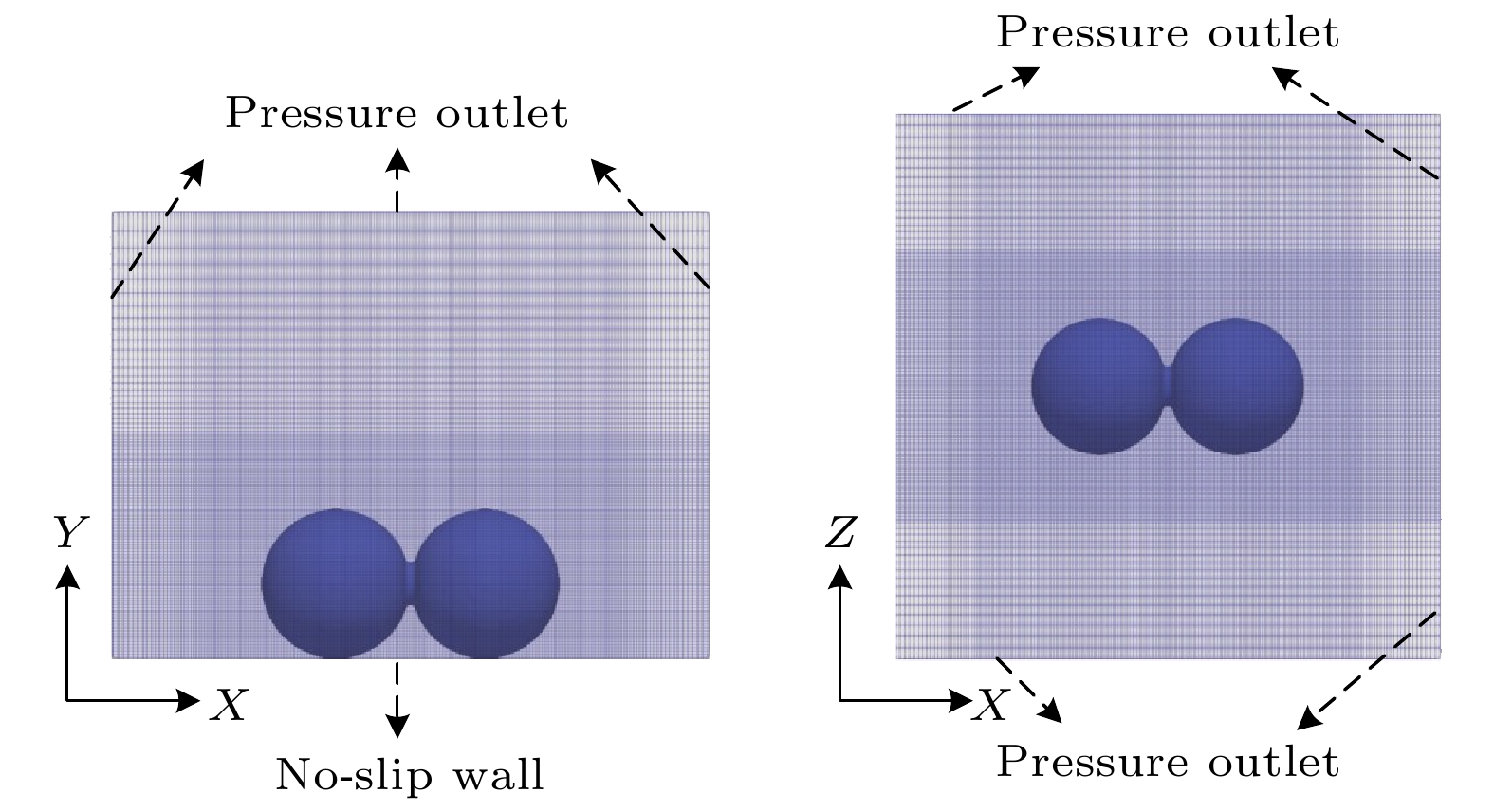

图 3 不同黏度比条件下液滴的聚并和自弹跳过程 (a), (f), (k) t* = 0.168; (b), (g), (l) t* = 0.604; (c), (h), (m) t* = 1.309; (d), (i), (n) t* = 2.686; (e), (j), (o) t* = 3.257

Fig. 3. Coalescence and jumping process of droplets with different viscosity ratios: (a), (f), (k) t* = 0.168; (b), (g), (l) t* = 0.604; (c), (h), (m) t* = 1.309; (d), (i), (n) t* = 2.686; (e), (j), (o) t* = 3.257.

图 6 (a) 不同黏度比时聚并自弹跳过程中表面能的变化; (b) 不同黏度比的液滴在跳起时具有的黏性耗散能; (c) 不同黏度比的液滴在跳起时刻具有的动能

Fig. 6. (a) Surface energy variation with different viscosity ratios during the coalescence and jumping process; (b) viscous dissipation energy of jumping droplets with different viscosity ratios at departure time; (c) kinetic energy of jumping droplets with different viscosity ratios at departure time.

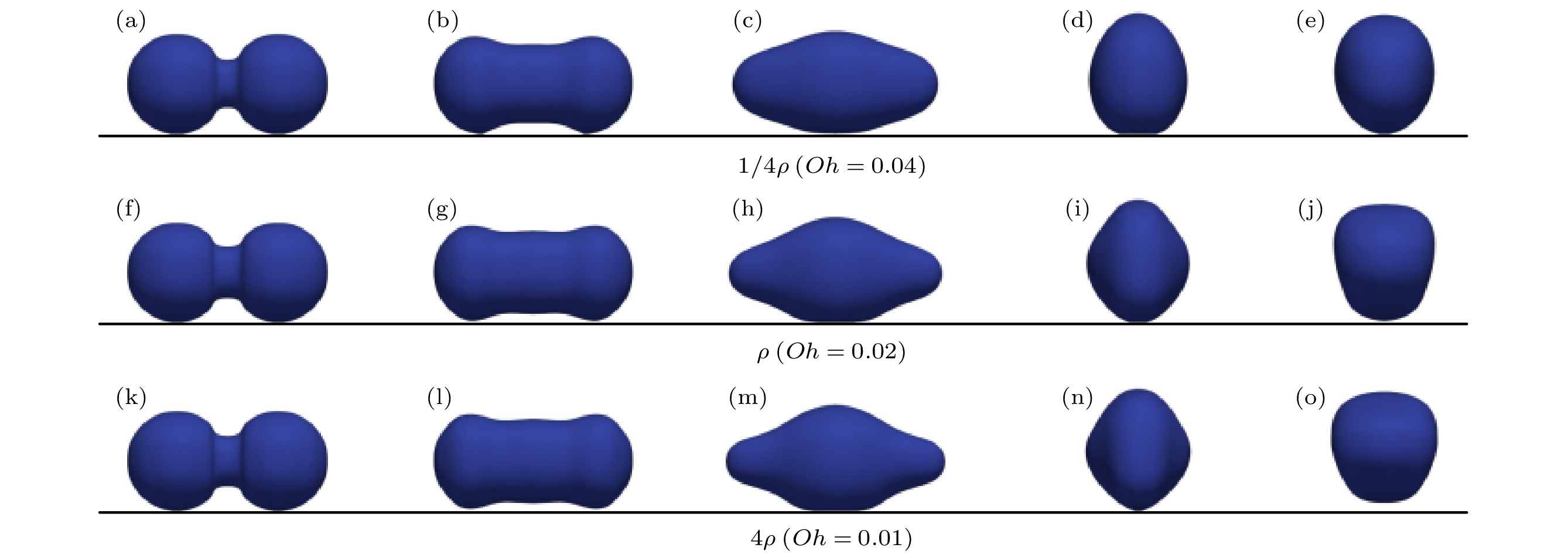

图 7 不同密度比条件下液滴的聚并和自弹跳过程 (a), (f), (k) t* = 0.168; (b), (g), (l) t* = 0.604; (c), (h), (m) t* = 1.309; (d), (i), (n) t* = 2.686; (e), (j), (o) t* = 3.257

Fig. 7. Coalescence and jumping process of droplets with different density ratios: (a), (f), (k) t* = 0.168; (b), (g), (l) t* = 0.604; (c), (h), (m) t* = 1.309; (d), (i), (n) t* = 2.686; (e), (j), (o) t* = 3.257.

图 8 (a) 密度变化对液滴跳离表面前所经历的各个阶段的无量纲持续时间的影响; (b) 密度变化对液滴跳离表面前所经历的各个阶段的真实持续时间的影响; (c)不同密度比时液滴质心处的无量纲弹跳速度

Fig. 8. (a) Effect of the change of density on the dimensionless duration of each stage prior to droplet jumping; (b) effect of the change of density on the real time of each stage prior to droplet jumping; (c) dimensionless jumping velocity of droplet with different density ratios.

图 9 (a) 不同密度比时聚并自弹跳过程中表面能的变化; (b) 不同密度比的液滴在跳起时具有的黏性耗散能; (c) 不同密度比的液滴在跳起时具有的动能

Fig. 9. (a) Surface energy variation with different density ratios during the coalescence and jumping process; (b) viscous dissipation energy of jumping droplets with different density ratios at departure time; (c) kinetic energy of jumping droplets with different density ratios at departure time.

表 1 流体物性参数

Table 1. Physical parameters of fluids.

温度T/℃ 表面张力系数σ/(N·m–1) 液体密度ρl/(kg·m–3) 液体黏度μl/(Pa·s) 气体密度ρg/(kg·m–3) 气体黏度μg/(Pa·s) 20 0.072 998 1.071 × 10–3 1.19 1.8 × 10–5 表 2 物性参数变化分别与真实弹跳速度和真实接触时间的关联度

Table 2. Relational degree of the change of physical parameters to the real jumping velocity and the real contact time, respectively, at droplet departure time.

参考序列/比较序列 黏度μl 密度ρl 关联度r0i, velocity (弹跳速度) 0.758 0.684 关联度r0i, time (接触时间) 0.741 0.771 -

[1] Boreyko J B, Chen C H 2009 Phys. Rev. Lett. 103 184501

Google Scholar

Google Scholar

[2] Chen X, Wu J, Ma R, Hua M, Koratkar N, Yao S, Wang Z 2011 Adv. Funct. Mater. 21 4617

Google Scholar

Google Scholar

[3] Miljkovic N, Enright R, Nam Y, Lopez K, Dou N, Sack J, Wang E N 2013 Nano Lett. 13 179

Google Scholar

Google Scholar

[4] He M, Ding Y, Chen J, Song Y 2016 ACS Nano 10 9456

Google Scholar

Google Scholar

[5] Han T, Kwak H J, Kim J H, Kwon J T, Kim M H 2019 Langmuir 35 9093

Google Scholar

Google Scholar

[6] Hou Y, Yu M, Chen X, Wang Z, Yao S 2015 ACS Nano 9 71

Google Scholar

Google Scholar

[7] Zhu J, Luo Y, Tian J, Li J, Gao X 2015 ACS Appl. Mater. Interfaces 7 10660

Google Scholar

Google Scholar

[8] Zhao Y, Luo Y, Zhu J, Li J, Gao X 2015 ACS Appl. Mater. Interfaces 7 11719

Google Scholar

Google Scholar

[9] Watson G S, Gellender M, Watson J A 2014 Biofouling 30 427

Google Scholar

Google Scholar

[10] Wisdom K M, Watson J A, Qu X, Liu F, Watson G S, Chen C H 2013 Proc. Natl. Acad. Sci. U. S. A. 110 7992

Google Scholar

Google Scholar

[11] Chavez R L, Liu F, Feng J J, Chen C H 2016 Appl. Phys. Lett. 109 011601

Google Scholar

Google Scholar

[12] Boreyko J B, Collier C P 2013 ACS Nano 7 1618

Google Scholar

Google Scholar

[13] Wiedenheft K F, Guo H A, Qu X, Boreyko J B, Liu F, Zhang K, Eid F, Choudhury A, Li Z, Chen C H 2017 Appl. Phys. Lett. 110 141601

Google Scholar

Google Scholar

[14] Liu F, Ghigliotti G, Feng J J, Chen C H 2014 J. Fluid Mech. 752 39

Google Scholar

Google Scholar

[15] Liu F, Ghigliotti G, Feng J J, Chen C H 2014 J. Fluid Mech. 752 22

Google Scholar

Google Scholar

[16] Farokhirad S, Morris J F, Lee T 2015 Phys. Fluids 27 102102

Google Scholar

Google Scholar

[17] Farokhirad S, Lee T 2017 Int. J. Multiphase Flow 95 220

Google Scholar

Google Scholar

[18] Shi Y, Tang G H, Xia H H 2015 Int. J. Heat Mass Transfer 88 445

Google Scholar

Google Scholar

[19] Wang K, Li R, Liang Q, Jiang R, Zheng Y, Lan Z, Ma X 2017 Appl. Phys. Lett. 111 061603

Google Scholar

Google Scholar

[20] Wang Y, Ming P 2018 AIP Adv. 8 065320

Google Scholar

Google Scholar

[21] Wang Y, Ming P 2019 Phys. Fluids 31 122108

Google Scholar

Google Scholar

[22] Wasserfall J, Figueiredo P, Kneer R, Rohlfs W, Pischke P 2017 Phys. Rev. Fluids 2 123601

Google Scholar

Google Scholar

[23] Khatir Z, Kubiak K Z, Jimack P K, Mathia T G 2016 Appl. Therm. Eng. 106 1337

Google Scholar

Google Scholar

[24] Chu F, Yuan Z, Zhang X, Wu X 2018 Int. J. Heat Mass Transfer 121 315

Google Scholar

Google Scholar

[25] Attarzadeh R, Dolatabadi A 2017 Phys. Fluids 29 012104

Google Scholar

Google Scholar

[26] Liang Z, Keblinski P 2015 Appl. Phys. Lett. 107 143105

Google Scholar

Google Scholar

[27] Gao S, Liao Q, Liu W, Liu Z 2018 J. Phys. Chem. Lett. 9 13

Google Scholar

Google Scholar

[28] Wang Y, Ming P 2021 J. Appl. Phys. 129 014702

Google Scholar

Google Scholar

[29] 刘天庆, 孙玮, 李香琴, 孙相彧, 艾宏儒 2014 63 086801

Google Scholar

Google Scholar

Liu T Q, Sun W, Li X Q, Sun X Y, Ai H R 2014 Acta Phys. Sin. 63 086801

Google Scholar

Google Scholar

[30] Mouterde T, Nguyen T V, Takahashi H, Clanet C, Shimoyama I, Quéré D 2017 Phys. Rev. Fluids 2 112001

Google Scholar

Google Scholar

[31] 王晨阳, 段倩倩, 周凯, 姚静, 苏敏, 傅意超, 纪俊羊, 洪鑫, 刘雪芹, 汪志勇 2020 69 100701

Google Scholar

Google Scholar

Wang C Y, Duan Q Q, Zhou K, Yao J, Su M, Fu Y C, Ji J Y, Hong X, Liu X Q, Wang Z Y 2020 Acta Phys. Sin. 69 100701

Google Scholar

Google Scholar

计量

- 文章访问数: 7403

- PDF下载量: 144

- 被引次数: 0

下载:

下载: